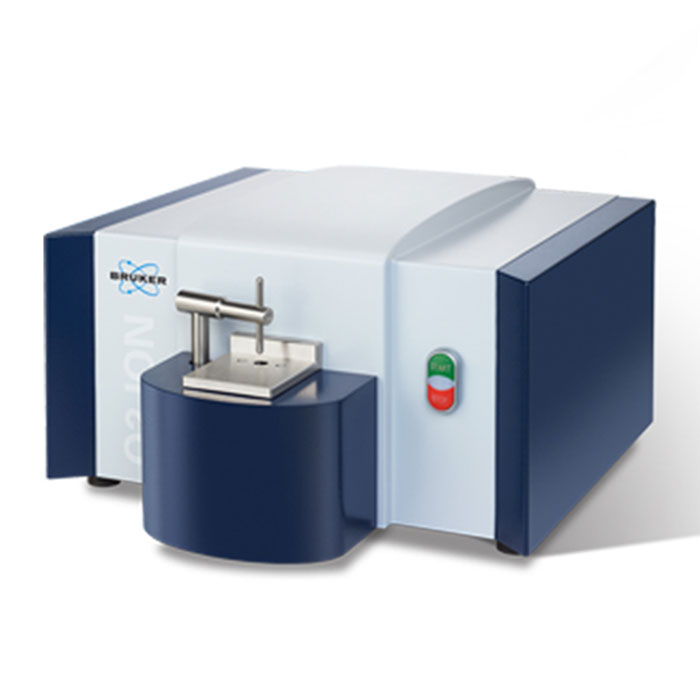

Ultra-compact Benchtop Spectrometer

The Q2 Ion is one of the smallest and lightest ultra-compact spark emission spectrometer for metal analysis available. It can easily be brought to a nearby site for analysis. Despite its low weight, it is suitable for applications in rugged environment.

Even though it is small, the Q2 Ion still offers consistently accurate and precise chemical analysis as well as Positive Material Identification (PMI) which includes CARBON content. Offering a multi-matrix system, users can have a system capable of measuring Fe/Steel, Aluminium, Copper, Tin and Zinc.

The inbuilt Elemental Suite Software works perfectly with the system and allows users to have complete control of their results. Meaning it can be set up so users have minimal human interference or error. Coupling that together with the Positive material identification (PMI) allows users to have an accurate report matched to alloys from all over the world.

Analytical Solution Packages (ASP)

• Different matrix calibration packages available

• ASPs cover all major elements & alloy groups

Spark Stand

• Maintenance-free

• Argon consumption 2.5l/min. during measurement

• Argon quality 4.8 (or better)

Electrical Data

• 100 to 240 V (50/60 Hz)

• 200 W during measurement, 25 W standby

• 16 A (240 V) slow blow fuse or 25 A (100 V) slow blow fuse

Dimensions & Weight

• Width 440 (600) mm / 17 (24) inches

• Height 530 (1280) mm / 22 (50) inches

• Depth 390 (630) mm / 15 (25) inches

• Weight ~ 28 (115) kg / ~ 62 (254) lbs

*values in (brackets) refer to floorstanding version

Applications

• Iron & Steel and its alloys

• Aluminium and its alloys

• Copper and its alloys

• Further applications upon request

All systems are supported by Trained Engineers who cover the whole over the UK.

• Help desk support from highly-skilled troubleshooting professionals, to isolate and resolve hard- and software problems

• Web-based remote instrument service for service diagnosis and applications support

• Merged reality support with Help Lightning – a virtual engineer at your side (video)

• Planned maintenance, according to your requirement

• Customer on-site repair and maintenance service

• Spare parts availability typically over night or within a few working days worldwide

• Compliance services for installation qualification, operational qualification / performance verification

• Site planning and relocation