Handheld XRF for Positive Material Identification (PMI)

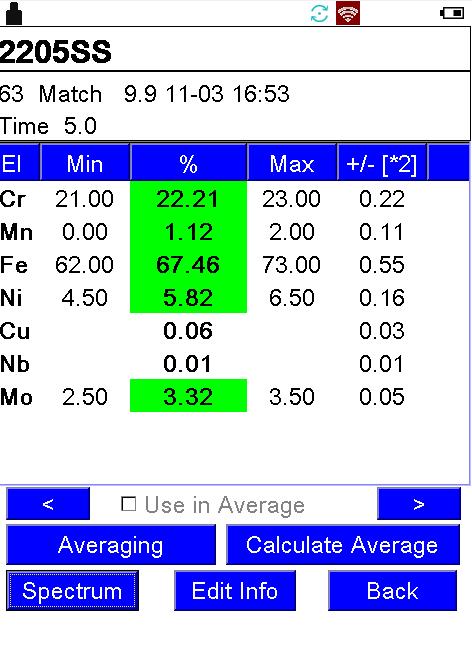

The Bruker S1 TITAN is a proven handheld XRF analyser for fast and accurate Positive Material Identification (PMI) in industrial environments. It verifies alloy grades in seconds, helping QA and inspection teams confirm material compliance before welding, fabrication, or maintenance shutdowns.

It is lightweight, rugged, and easy to use. The S1 TITAN delivers laboratory-level accuracy directly in the field. Simply point and shoot and results appear instantly with full element composition and grade match.

The patented DetectorShield™ protects the detector window from punctures or debris, keeping you operational in demanding environments like refineries, fabrication yards, or construction sites.

For hard-to-reach areas, the analyser can be mounted on an extension pole, allowing safe PMI checks on overhead pipework, flanges, and storage tanks – no ladder required.

Wireless connectivity enables instant data transfer for QA/QC reporting, material traceability, and audit compliance.

S1 TITAN Models and Specifications

S1 TITAN Model 500

Elemental Range: Titanium (Ti) to Uranium (U).

Best For: Standard alloy analysis without light element detection.

S1 TITAN Model 500S

Elemental Range: Magnesium (Mg) to Uranium (U).

Best For: Comprehensive analysis of light and heavy elements, offering enhanced flexibility.

S1 TITAN Model 800

Elemental Range: Magnesium (Mg) to Uranium (U).

Best For: Premium performance in light element detection, delivering exceptional precision for Magnesium, Aluminium, and Silicon analysis.

Applications:

- Oil & Gas / Petrochemical: Verify piping, valves, and flanges during shutdown or turnaround.

- Power Generation: Check heat exchanger and turbine components for grade conformity.

- Aerospace & Defence: Confirm alloys in structural fasteners, turbine blades, and repair parts.

- Automotive & Engineering: Inspect welds, castings, and machined components.

- Metal Fabrication: Prevent mix-ups and confirm incoming material before welding or machining.

- Recycling & Scrap Sorting: Identify precious metals contents for valuation.

- Pharmaceutical & Food Industries: Confirm stainless grades in production equipment for hygiene compliance.

- Construction & Infrastructure: Validate reinforcement bars, bolts, and fittings on site.

Local Support from Labquip NDT

Labquip NDT provides full support across the UK (Scotland, England, and Wales) through our regionally based Technical Sales, Support, and Service Engineers including:

- On-site demonstrations and operator training

- Preventative maintenance and calibration from our lab

- Application guidance to match the right setup to your process

- Fast access to consumables, parts, and accessories