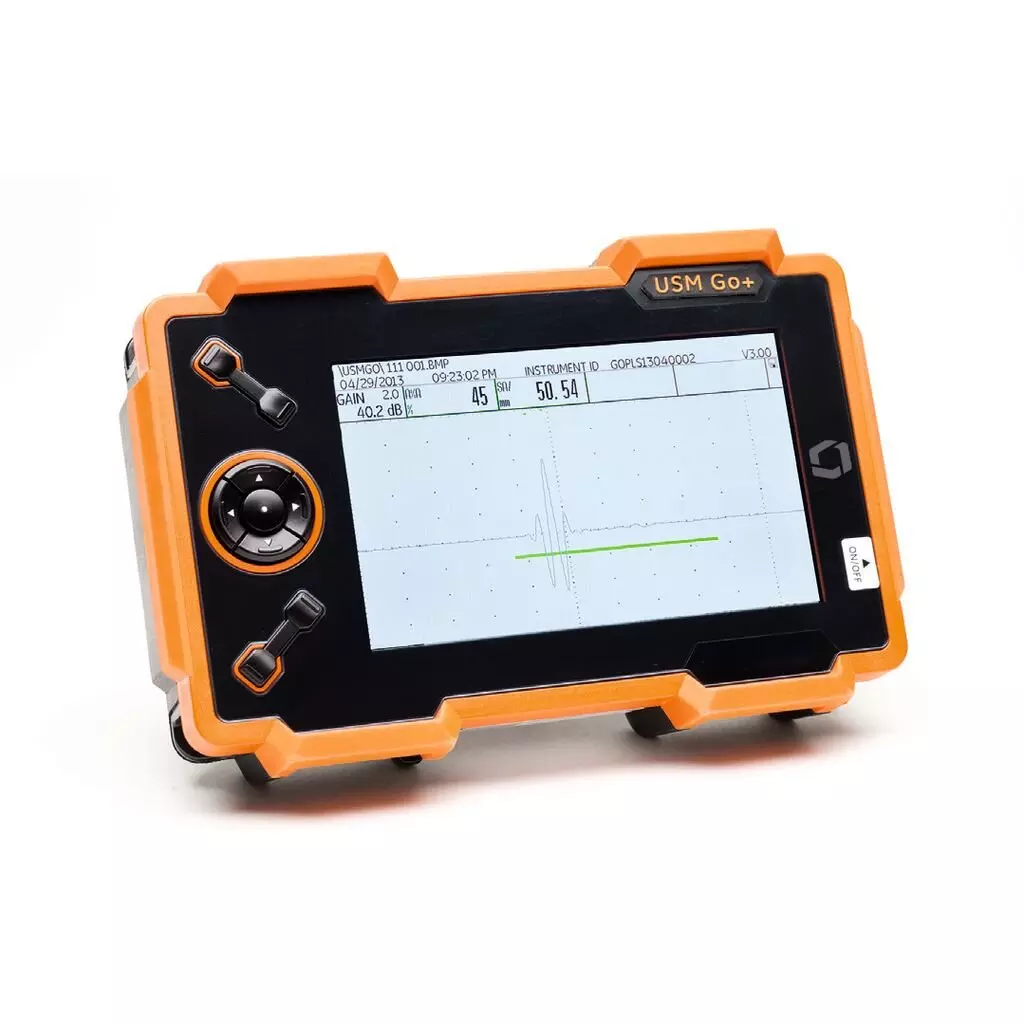

The Krautkrämer USM Go+ is the compact ultrasonic flaw detector used across aerospace, power generation, automotive, rail and oil & gas inspection work. Its light weight, sealed housing and clear display make it a practical tool for UT technicians who move between plant areas, confined spaces and outdoor locations.

Beyond its core portability there are several built-in functions that supports consistent ultrasonic evaluation:

- Trigonometric flaw location with curvature correction for welds

- Colour Leg indicator for angle-beam interpretation

- Two independent gates for monitoring and triggering

- Auto-80 reference level for quick standardisation

- IP67 sealing for dust, splash and temporary immersion

- Arrow-key keypad for gloved operation

- RF display and narrow-band filters for composites and attenuative metals

- Low-noise digital amplifier for improved SNR

- Square-wave pulser when deeper penetration is required

- BEA (Backwall Echo Attenuator) for coarse-grain castings

- Phantom echo indicator for differentiating false responses

- DGS and DAC/TCG tools depending on configuration

- Third gate and thickness recorder on advanced models

Configurations include Base, Standard, Standard with DGS, and Advanced (GEIT1480176 through GEIT1480180), allowing users to match software capability to their inspection scope.

Applications

1.Weld Inspection (Carbon steel, stainless, duplex, aluminium)

- Used for site welds, piping, pressure systems and structural fabrications:

- Trigonometric calculations with curvature correction

- AWS D1.1 sizing

- DAC/TCG

- DGS (on applicable models)

- Colour Leg indicator

2. Forgings and Castings (Alloy steels, nickel alloys, cast iron, aluminium).

- Applied to shafts, rings, billets, machined components and castings

- Manual PRF adjustment

- Phantom echo indicator

- DGS

- Backwall Echo Attenuator (BEA)

3. Rail Components (Rail steel, axles, bogie castings)

- Practical for depot and trackside inspection

- High PRF (up to 2000 Hz)

- 850 g instrument weight

- Compact body and straightforward ergonomics

4. Composite Materials (CFRP, GFRP, honeycomb)

- Used in aerospace, renewables and lightweight structures

- RF display

- Two gates with B-start from Gate A

- High-slope TCG (120 dB/µs)

- Depth indication within laminate layers

5. For more Demanding UT Conditions or complex materials

- Narrow-band filters

- Low-noise amplifier

- Square-wave pulser

Labquip NDT Support

- Technical advice on probes, wedges, cables and calibration blocks

- Application guidance for weld UT, forged product inspection, composite evaluation and rail work

- Onsite or remote demonstrations

- Waygate-certified service, repair and calibration management

To evaluate the Krautkrämer USM Go+ on your materials, request a demonstration with our NDT team. We can advise on the best model configuration and accessories for your workflow.