Part Number: UT150M5734 USM 100 Standard Instrument Part Number: UT150M5735 USM 100 Pro Instrument

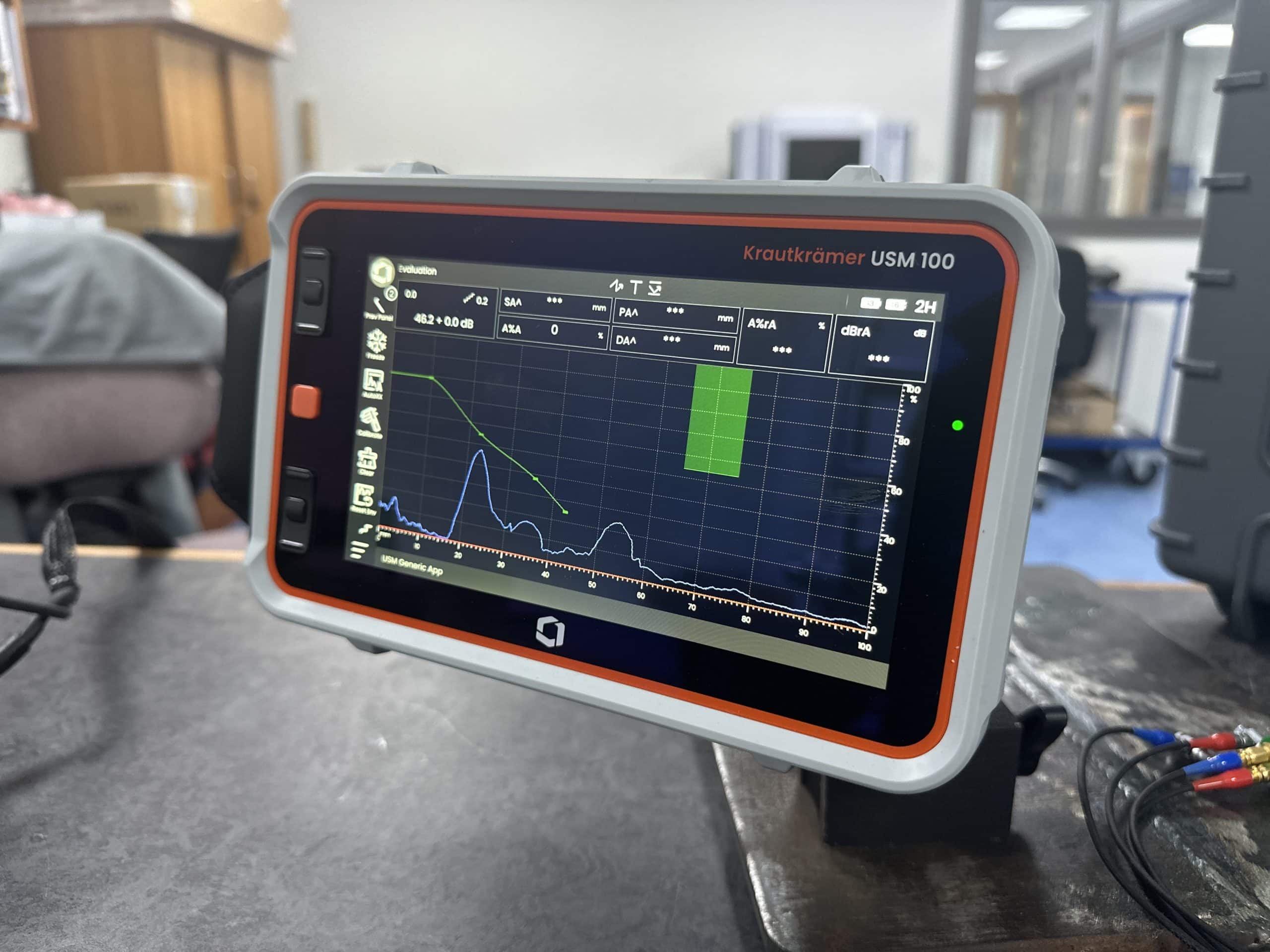

Krautkrämer USM 100 Flaw Detector

Portable digital ultrasonic flaw detector for welds, corrosion, forgings and in-service inspection

The Krautkrämer USM 100 from Waygate Technologies is a portable ultrasonic flaw detector designed for day-to-day industrial inspections. It provides a clean A-scan, predictable gate behaviour and a simple digital interface that reduces setup time on welds, corrosion routes and general component checks.

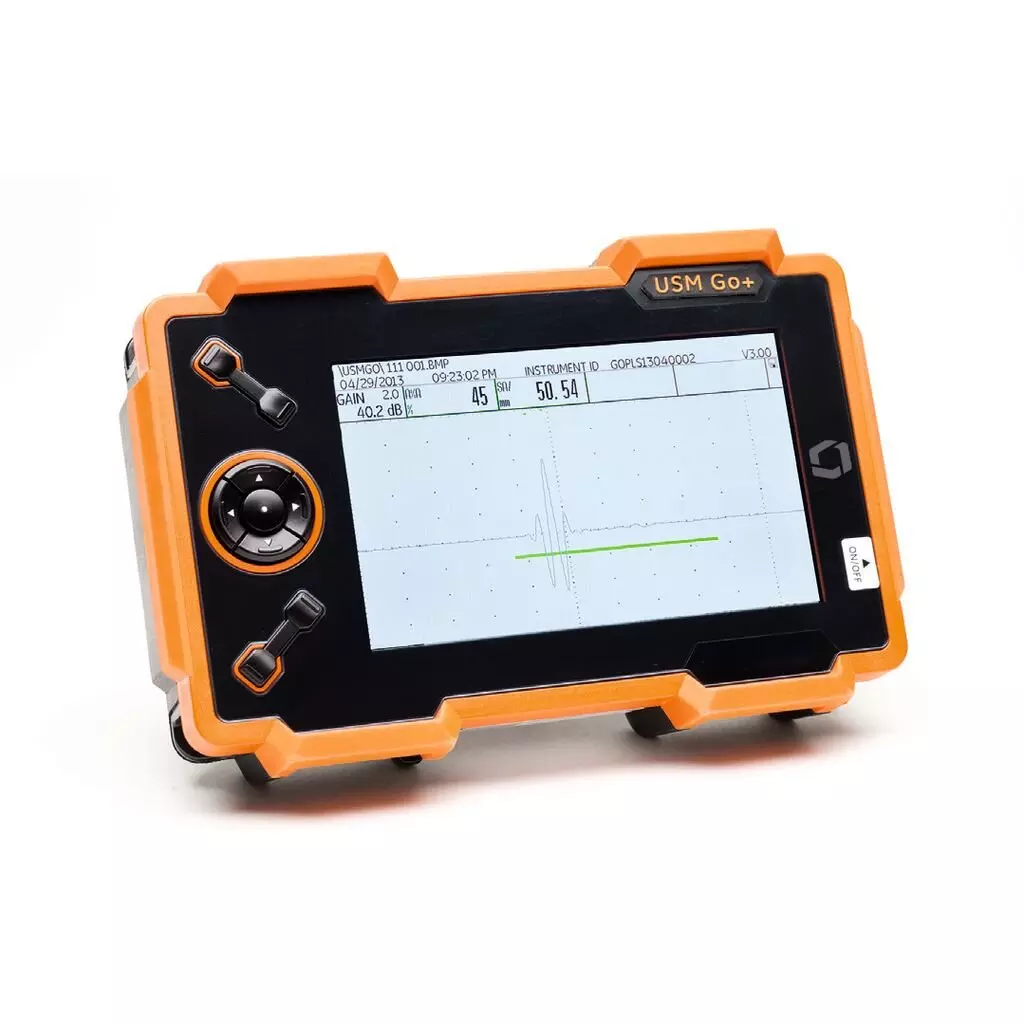

The touchscreen remains usable with gloves, and the control layout follows the familiar logic of the Krautkrämer family, keeping transition time low for teams already using USM Go+ or USM 36. Two configurations are available: Standard and Pro. The Pro version adds advanced UT evaluation features for organisations working to tighter inspection codes.

Applications

1. Weld Inspection (Carbon steel, stainless, duplex, Cr-Mo alloys).

Designed for common weld tasks in oil & gas, power generation, fabrication and structural steel.

- Angle-beam shear-wave inspection

- Root and sidewall evaluation

- Fusion and toe-crack assessment

- General pipeline, structural and pressure-system weld checks

- Clear A-scan visibility and stable gate behaviour support consistent interpretation across field and facility work.

2. Corrosion Assessment (Pipelines, tanks, vessels, structural steel)

Used for general corrosion mapping and wall-loss measurement in energy and process industries.

- Dual-element corrosion probes

- Localised pitting checks

- Remaining-wall-thickness confirmation

- Routine integrity monitoring on pipework, tank floors and structural assets

- Ideal for long corrosion routes where quick setup and clean A-scans reduce inspection time.

3. Thickness Measurement (Automotive, aerospace, fabrication)

Provides stable through-wall readings for thin and mid-range sections.

- Sheet and plate verification

- Formed panels and structural parts

- Machined components in aluminium, steels and alloys

- General fabrication and production QC

4. Forging & Casting Inspection (Shafts, rings, billets, housings)

Useful for identifying internal defects in metallic products where attenuation or coarse grain structure can affect the signal.

- Forged shafts and discs

- Rolled rings and long products

- Cast housings, brackets and industrial components

- Flexible pulser control helps with inclusions, shrinkage and general internal-quality evaluation.

5. Rail Components (Axles, wheels, rail steel)

Practical for general UT checks in rolling-stock maintenance and depot inspection.

- Flaw screening on axles and wheels

- Near-surface indication detection on rail steel

- Component life-extension assessments

6. Composite Structures (CFRP, GFRP, honeycomb panels)

Suitable for lightweight materials in aerospace, transport and renewables.

- Delamination detection

- Disbond identification

- Core-integrity checks

7. Nuclear Plant Inspection

Chosen for stable A-scan response and predictable setup behaviour in controlled environments.

- Welds in safety-critical pipework

- Corrosion and wall-loss screening

- General UT tasks inside nuclear facilities

Labquip NDT Support

Labquip NDT UK provides practical support before and after purchase:

- Setup for weld, corrosion and product-inspection workflows

- Probe and wedge recommendations matched to your materials

- Guidance on USB/Ethernet reporting and data formats

- Waygate-approved calibration, service and repair

To see how the Krautkrämer USM 100 performs on your welds, pipework or components, contact us to arrange a demonstration.