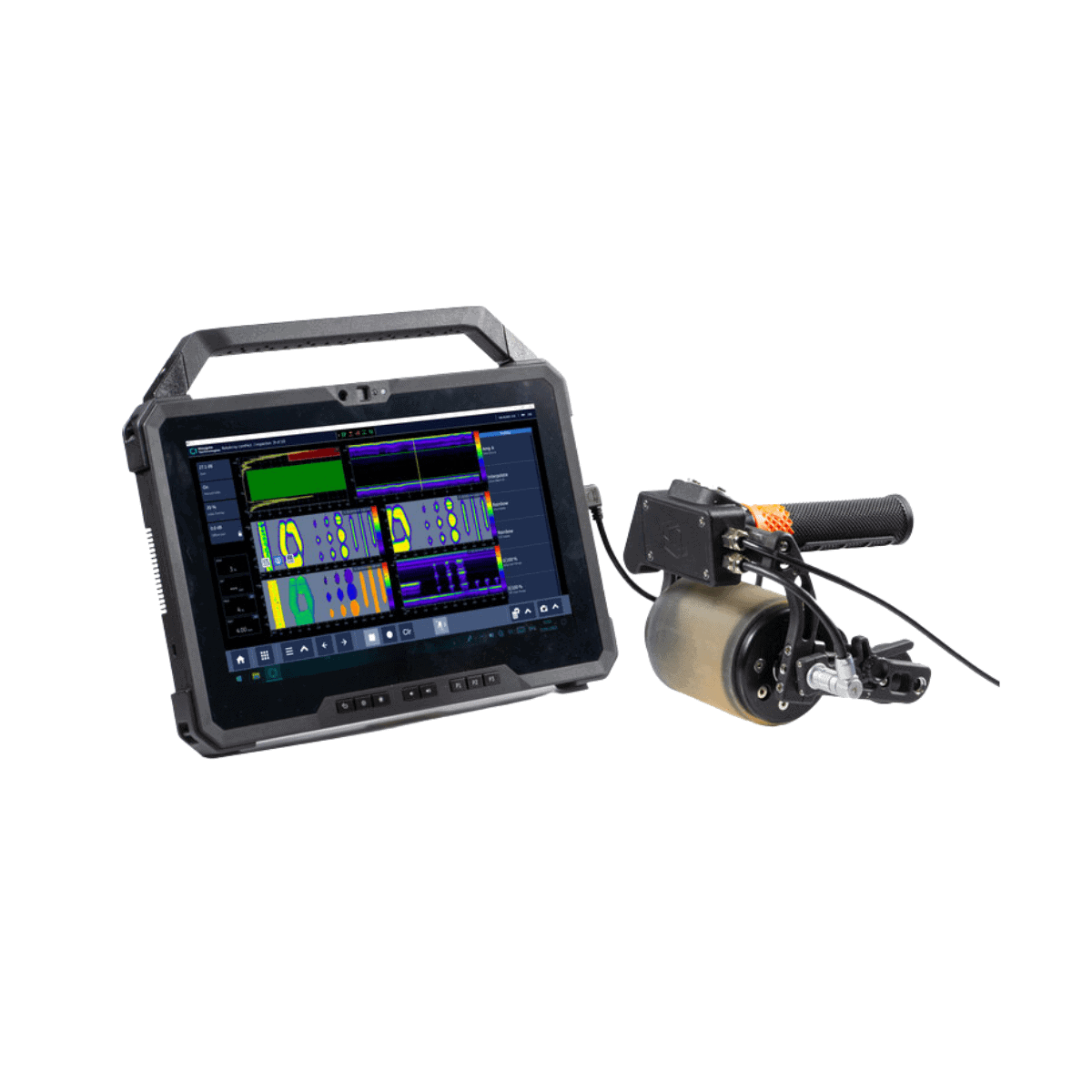

The Krautkrämer RotoArray comPAct is a manual phased array scanner designed for technicians who need encoded weld and corrosion data without the size, weight or setup time of a mechanised system. The scanner’s roller layout provides steady, controlled movement, reducing lift-off and signal variation during long scans. Its compact frame allows access to pipe racks, structural welds, tank shells and composite panels where larger scanners cannot be used.

When used with Waygate instruments such as Mentor UT or USM 100, the comPAct provides dependable sectorial scans and corrosion maps with straightforward setup and low operational overhead. It is well suited to field inspection teams working across fabrication, energy, aerospace, marine, utilities and general industrial maintenance.

For corrosion mapping, the rolling base maintains constant coupling pressure, giving more stable A-scans and C-scans. For weld inspection, the motion is smooth enough that operators get consistent sectorial scans even on long welds.

Applications

1. Weld Inspection (Carbon steel, stainless, duplex, nickel alloys)

- Used for encoded manual weld scanning across fabrication, oil & gas, utilities and structural steel.

-

Circumferential and long-seam welds on pipelines

-

Structural welds on frames, supports and assemblies

-

Pressure-vessel and tank welds

-

Nozzle and small-diameter welds where access is restricted

-

General fabrication weld checks

- The stable roller base supports consistent probe movement, improving repeatability during sectorial scanning and root/sidewall evaluation.

2. Corrosion Mapping (Pipelines, tanks, vessels, marine and plant assets)

- Practical for encoded corrosion routes where repeatable movement and simple setup reduce inspection time.

-

Tank shell and roof corrosion assessment

-

Pipeline and flowline corrosion mapping

-

Marine structures exposed to saltwater environments

-

Corrosion screening on plant pipework and process equipment

-

Remaining wall thickness checks on aging assets

- The integrated encoder records accurate position data, supporting C-scan production and structured reporting.

3. Composite Structures (Aerospace, wind energy, automotive, marine)

- Suitable for large composite surfaces where a smooth rolling scan improves data quality.

-

CFRP and GFRP skins and laminates

-

Wind turbine blade inspection

-

Automotive composite panels

-

Marine composite structures

-

Honeycomb and bonded-panel assessments

- The roller design maintains consistent coupling pressure, helping detect delamination, disbonding and core defects.

4. Aerospace MRO & Production

- Useful for manual phased array checks during maintenance or production-quality control.

-

Aircraft structural panels

-

Repair patch verification

-

Composite component QC

-

Localised defect investigation in metallic and non-metallic structures

- Its compact size allows scanning in confined spaces often encountered in MRO environments.

5. General Industrial UT Scanning

- Applicable where encoded manual scanning is required but full mechanisation is impractical.

-

Welds inside fabrication workshops

-

Assets in restricted or elevated areas

-

Field repairs requiring quick deployment

-

Maintenance teams carrying portable UT kits

- The comPAct provides a reliable, low-maintenance, field-ready scanning option.

Labquip NDT Support

-

Setup guidance for weld and corrosion-mapping workflows

-

Probe and wedge recommendations matched to your materials and geometry

-

Assistance with Mentor UT and USM 100 PAUT configurations

-

Waygate-approved service, calibration and repair

-

On-site demonstrations across the UK

To see how the Krautkrämer RotoArray comPAct performs on your welds, pipelines or composite structures, contact our NDT team to arrange a demonstration.