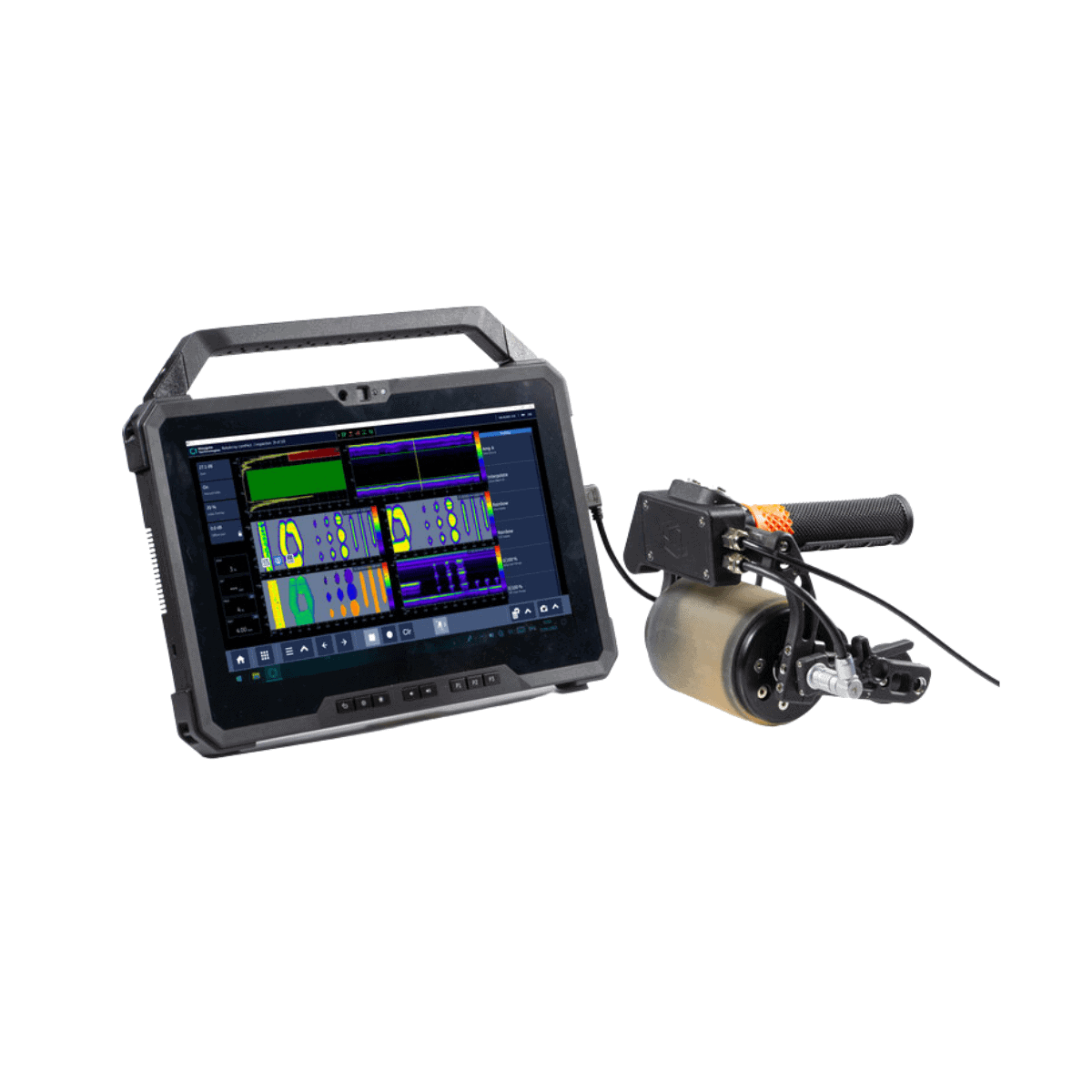

The Krautkrämer Mentor UT is Waygate Technologies phased array ultrasonic testing (PAUT) system designed for industries where repeatability, workflow control and traceability are essential. Instead of relying on manual menu navigation, Mentor UT uses customisable app-based procedures that guide technicians through each step of the inspection. This reduces setup time and helps organisations maintain compliance with written procedures, inspection codes and customer specifications.

Mentor UT combines high-performance phased array capability with conventional UT channels, making it suitable for weld inspection, spot weld evaluation, adhesive-bond testing, corrosion mapping and composite assessments. Its IP65 build and bright touchscreen support reliable operation in fabrication shops, aerospace hangars, railway depots and energy facilities.

With its structured workflows, clear imaging and strong data-management tools, Mentor UT helps teams deliver consistent, traceable PAUT results across field and plant environments.

Applications

1. Weld Inspection (Carbon steel, stainless, duplex, nickel alloys)

- Designed for organisations working to strict weld-quality codes in energy, fabrication, utilities and manufacturing.

-

Circumferential and long-seam welds

-

Multi-pass welds and complex joint geometries

-

Fusion-line and sidewall evaluation

-

Root, cap and mid-wall assessment

-

High-integrity welds in power generation and process industry

- Guided workflows help maintain consistent PAUT setup across teams, reducing interpretation variation.

2. Aerospace Structures & Adhesive Bonds

- Used for composite structures and bonded assemblies in MRO and production environments.

-

CFRP/GFRP skins and laminates

-

Adhesive bond inspection

-

Honeycomb and sandwich panels

-

Localised repair patch evaluation

-

Composite QC during manufacturing

- Phased array imaging supports accurate detection of delamination, disbonding and core defects.

3. Automotive Spot-Weld & Component Inspection

- Applied in automotive R&D, body-in-white (BIW) production and general component QC.

-

Spot-weld integrity checks

-

Multi-layer panel evaluation

-

Structural adhesive bond integrity

-

Formed aluminium/steel component inspection

-

Material-thickness confirmation

- The system supports fast, repeatable spot-weld testing for high-volume environments.

4. Rail & Critical Industrial Components

- Reliable for regulated inspections in rail depots, heavy industry and maintenance teams.

-

Railway axles and wheel components

-

Underframe and bogie structures

-

Pressure-system components

-

Forgings, shafts and discs

-

In-service inspections in harsh conditions

- The IP65 housing performs well in depot, yard and plant environments.

5. Corrosion & Wall-Loss Assessment

- Suitable for manual or encoded corrosion-mapping tasks.

-

Pipelines and flowlines

-

Storage tanks and process vessels

-

Marine structures and plant assets

-

Localised pitting and wall-loss checks

- Connectivity options simplify reporting and integration with integrity-management systems.

Labquip NDT Support

Labquip NDT UK supplies Mentor UT with full application support across phased array workflows. Our team provides:

-

Setup guidance for weld, spot-weld, composite and corrosion workflows

-

Assistance in building and optimising app-based procedures

-

Probe, wedge and scanner selection matched to materials and geometries

-

Data-format, reporting and connectivity support

-

Waygate-approved service, calibration and repair

-

On-site demonstrations and workflow reviews across the UK

To see how Mentor UT performs on your welds, bonds, spot welds or critical components, contact our NDT team to arrange a demonstration.