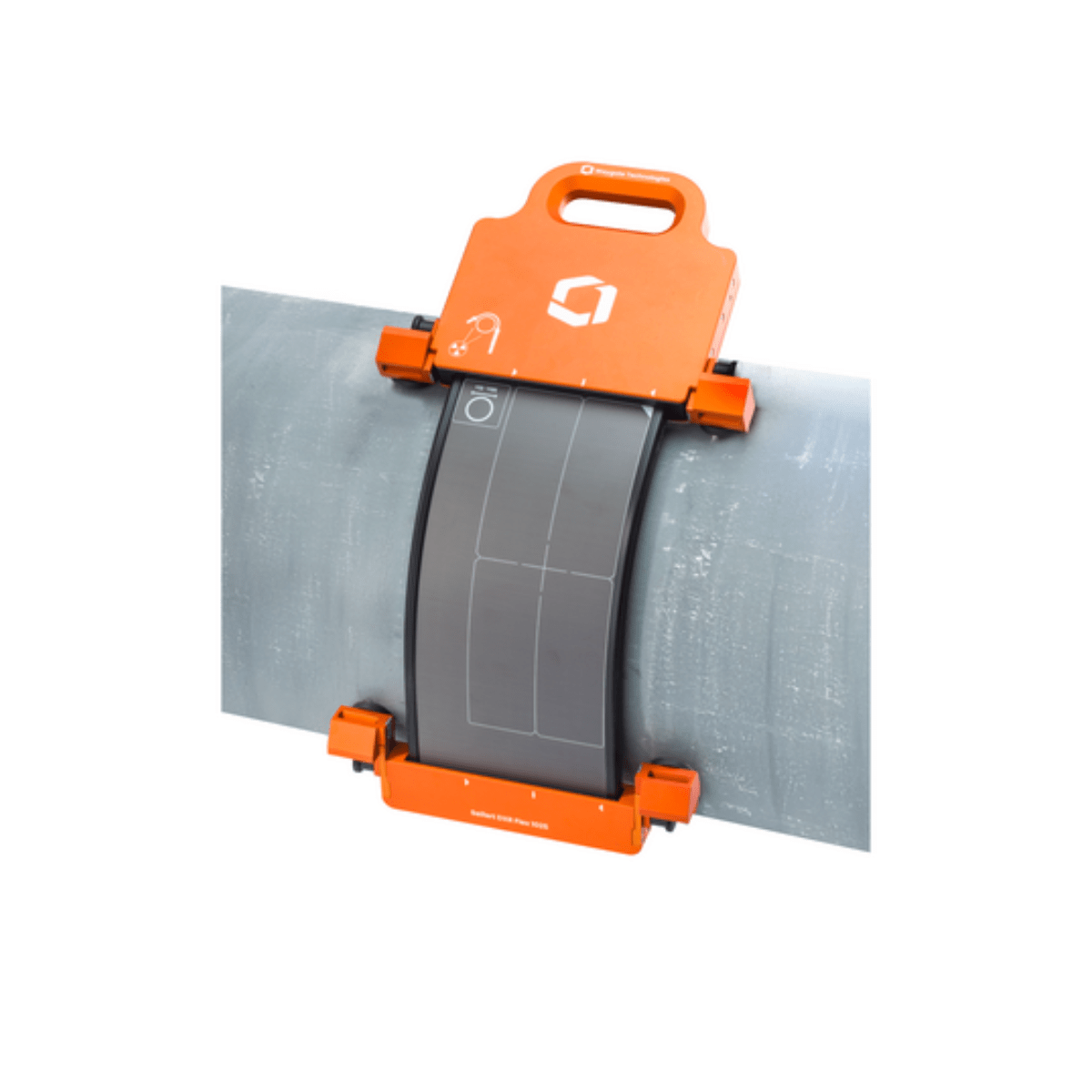

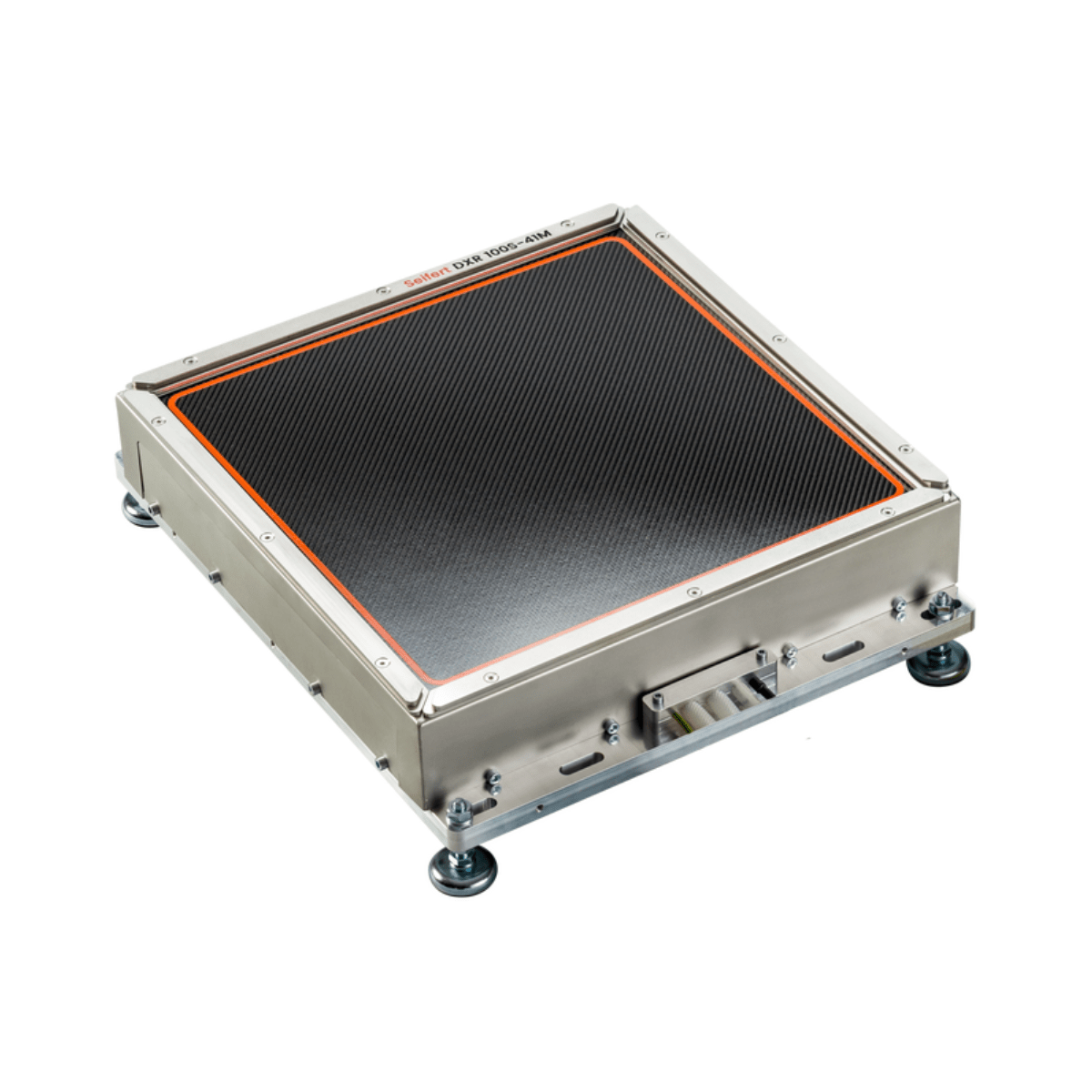

The Waygate Technologies DXR Flex 1025 and 1043 are portable, bendable digital X-ray detectors designed for radiography where a standard flat panel cannot achieve proper contact. Their flexible sensor layer conforms to pipes, elbows, tanks and other curved surfaces, improving image quality in locations where film or rigid DR panels are difficult to position.

The DXR Flex 1025 provides high-resolution imaging for welds and small-diameter pipework.

The DXR Flex 1043 offers a larger active area and higher sensitivity for corrosion routes, tank inspections and general DR tasks.

Both detectors support ISO 17636-2 and ASTM E2737 workflows and are suitable for field teams working in oil & gas, power generation, aerospace, automotive and industrial maintenance.

Applications

1.Pipeline & Tank Weld Inspection

Flexible detectors conform to curved pipe surfaces, elbows and tank walls for clear radiography of weld seams, root defects, porosity, misalignment and corrosion.

2. Power Generation Equipment

Used on pressure vessels, boiler tubes, turbine components and other curved surfaces where stable contact is needed for consistent DR images.

3. Automotive & Heavy Machinery

Suitable for castings, engine housings and structural components where complex geometry prevents the use of a rigid DR panel.

4. Aerospace Composites & Metal Structures

Supports radiography of composite layups, bonded joints and aerospace-grade metallic parts where panel flexibility improves placement and image consistency.

5.General Curved-Surface Radiography

For any inspection where contact with irregular or non-flat surfaces is required, including in-service corrosion checks and difficult-to-access areas.

Labquip NDT Support

- Labquip NDT provides pre-purchase guidance and post-purchase setup support for the DXR Flex range.

- We help match the correct detector (1025 or 1043) to your weld, corrosion or general DR workflow and assist with Rhythm Insight RT configuration and basic operator training.

- Our local team supports customers across the UK, ensuring a smooth transition to portable digital radiography.