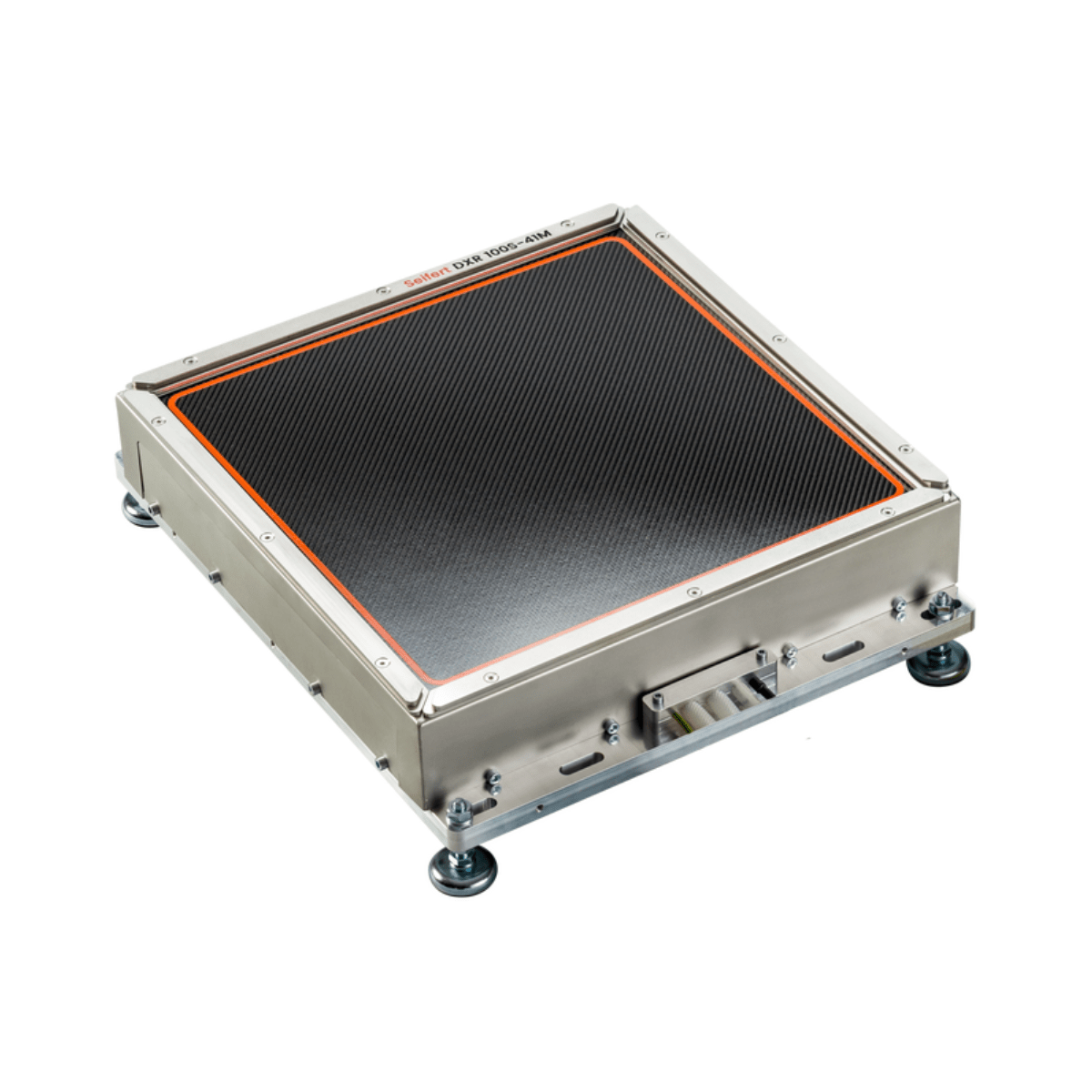

The Waygate Technologies DXR 100S/200S-41M are stationary digital X-ray detectors designed for modernising existing radiography cabinets and systems. They replace film, image intensifiers or older flat panels with a high-quality digital detector package that increases sensitivity, speeds up inspection and delivers consistent results across shifts.

These detectors allow operators to upgrade ageing radiography equipment without replacing the entire system. With a large imaging area, higher resolution and fast image acquisition, they support high-volume production environments such as aerospace, foundries, pipe mills and precision component manufacturing.

The detectors integrate into automated inspection setups and support real-time imaging for increased throughput. Waygate’s architecture ensures long-term stability in industrial environments where uptime matters.

Labquip NDT provides support for selecting the right detector configuration, cabinet integration planning and workflow setup for production radiography.

Applications

1.Turbine Blades & Aerospace Components

High-resolution imaging for internal defects, cooling channel checks and thin-section structures.

2.Weld Inspection

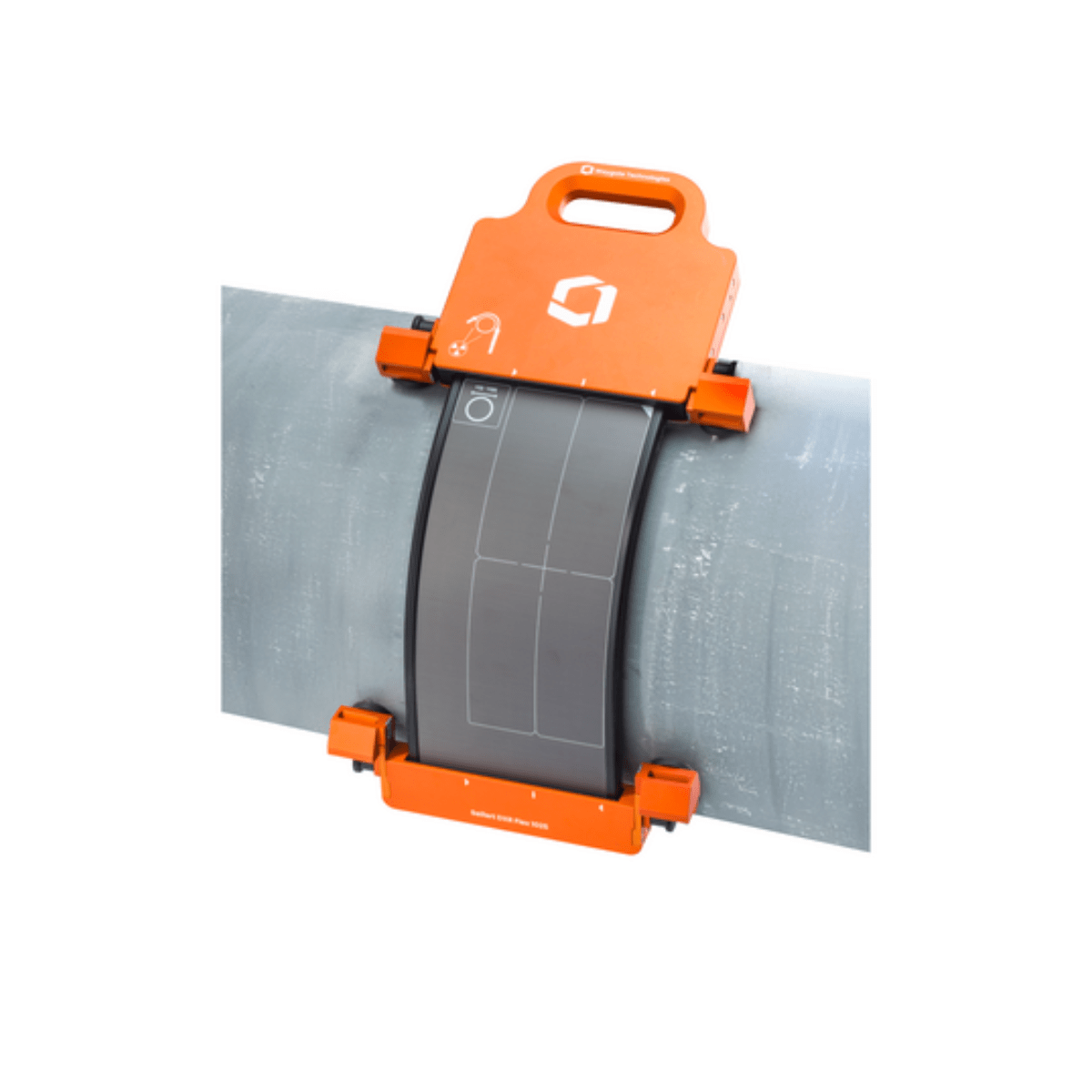

Digital radiography for welds in pipe mills, structural assemblies and pressure-boundary components.

3. High-Throughput Castings

Rapid image acquisition for foundries producing aluminium, steel or nickel-alloy castings.

4. Pipe Manufacturing

Inline or cabinet-based inspection of long-seam welds, spiral welds and mill qualification.

5. Electronics & Assemblies

Inspection of solder joints, PCB components and complex assemblies requiring high detail.

6. Automated Inspection Systems

Compatible with integrated manipulation systems and automated cabinet workflows.

DXR S200 PRO (Optional Upgrade)

High-speed detector for automated and real-time inspection

-

Up to 30 fps full-resolution imaging

-

Premium image quality for high-duty industrial usage

-

Suited for automated inline systems and real-time inspection environments

Labquip NDT Support

Labquip NDT provides pre-purchase guidance and integration support for stationary DR detectors. We assist with:

-

Selecting the appropriate detector (100S / 200S / S200 PRO) for your cabinet or inspection line

-

Planning retrofit integration for existing X-ray systems

-

Workflow setup and operator guidance for digital radiography workflows