The Bruker Q8 MAGELLAN is Bruker’s top-tier floor-standing PMT-based spark OES designed for primary metal producers, melt shops and high-specification laboratories requiring trace-level impurity control. PMT detectors provide the sensitivity needed for elements with low-UV emission lines and those associated with inclusion chemistry such as oxygen, sulphur, nitrogen and microalloying additions.

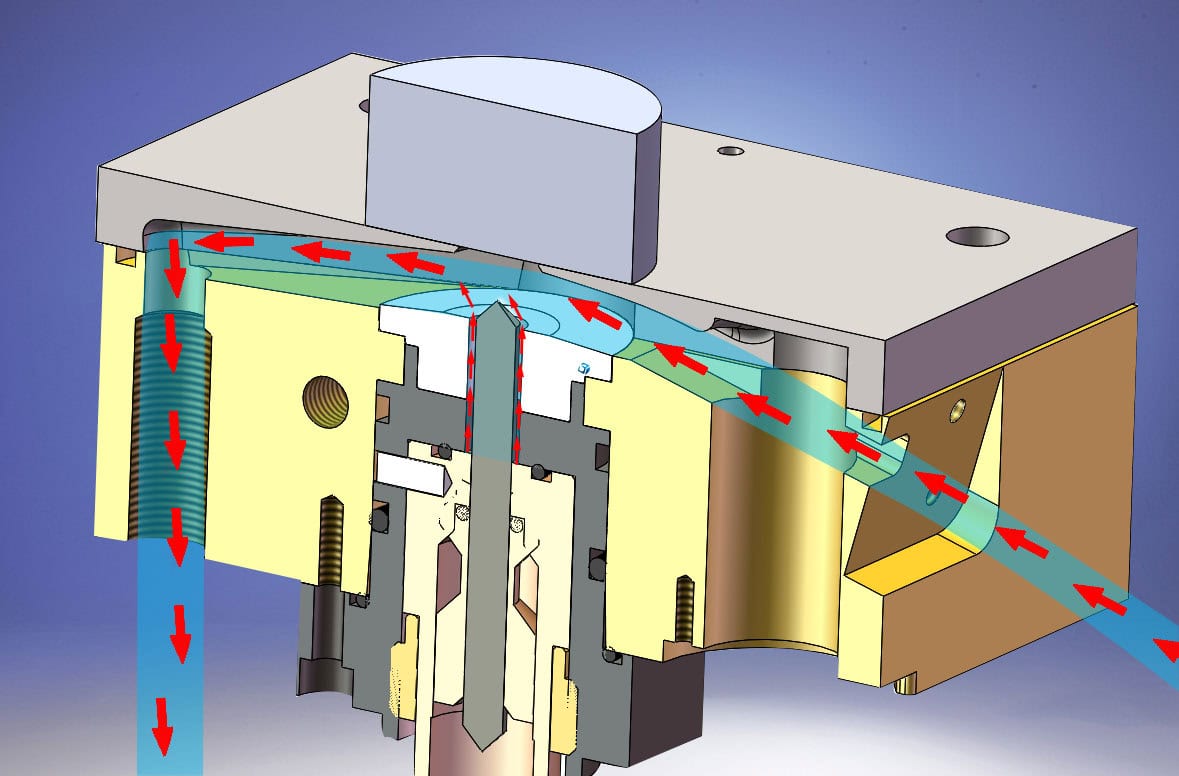

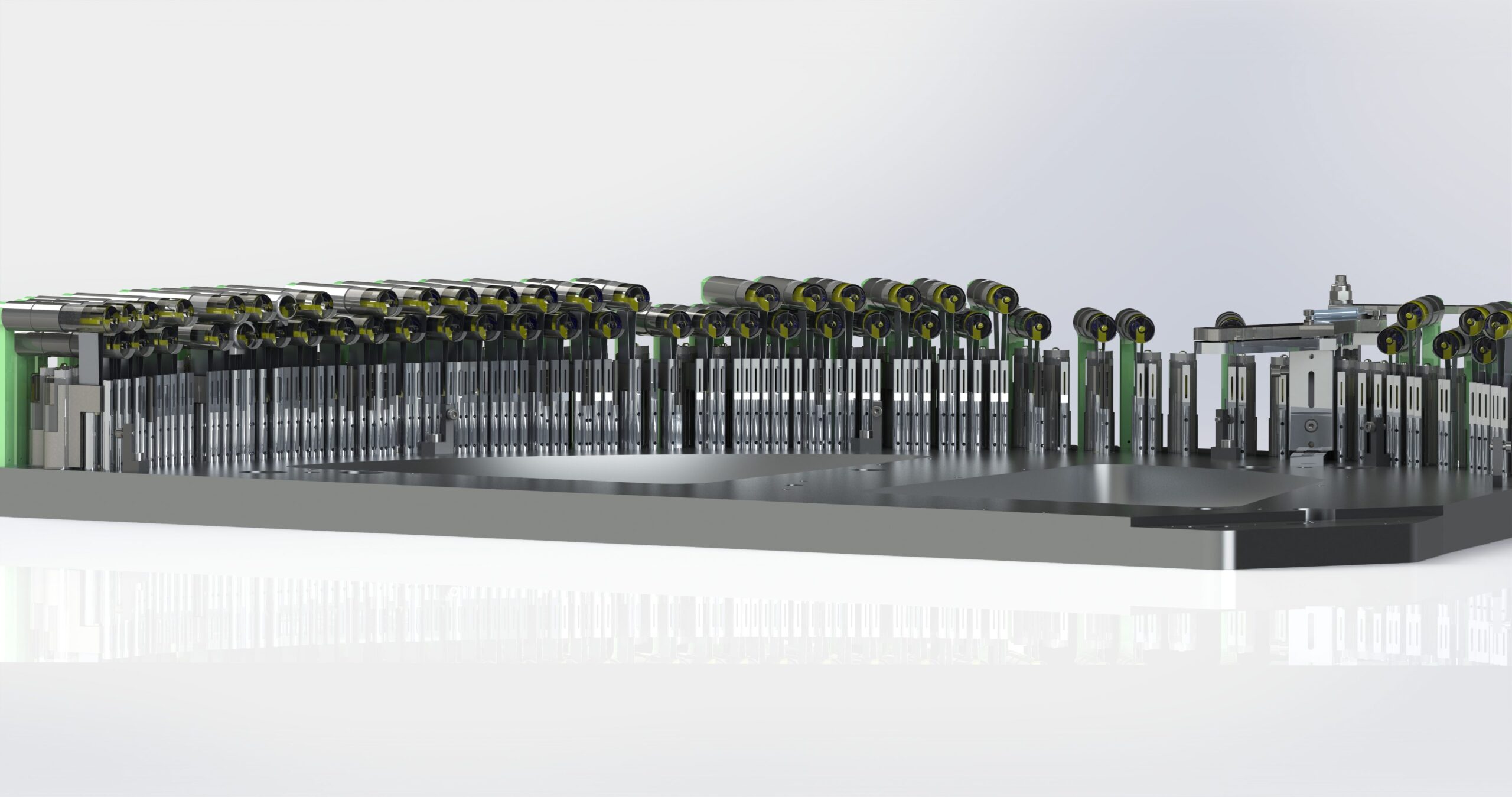

The vacuum-sealed optical system maintains stability over long operating periods without the drift typically seen in purge-based optics. The spark stand supports high sample throughput with consistent argon flow and mechanical rigidity, making the instrument suitable for 24/7 melt-shop environments.

The Q8 MAGELLAN is typically selected where the priority is clean steel, precise process control, or high-purity non-ferrous production, and where small variations in residual elements or inclusions directly affect mechanical performance and downstream processing.

Applications

1. Steel & Iron – Melt Control and Impurity Management

Used in steelworks to measure carbon, sulphur, phosphorus, nitrogen, microalloying elements and inclusion-related lines essential for clean-steel production and process adjustments.

2. Inclusion Analysis in Steels

Supports detection of oxide, sulphide and other non-metallic inclusion indicators relevant to casting cleanliness, defect prevention and high-performance alloy production.

3. Copper & High-Purity Alloys

Suitable for oxygen control, trace metallic impurities and conductivity-critical copper grades used in electrical and electronic applications.

4. Non-Ferrous Metals

Covers aluminium, magnesium, zinc, tin, nickel, cobalt, lead and related alloys requiring trace-level control for casthouse and specialty alloy production.

5. Precious Metals & Specialty Applications

Optional configurations support platinum-group metals, jewellery alloys and other high-value materials requiring sub-ppm analysis.

Labquip NDT Support

- System configuration for specific alloy bases and impurity ranges

-

Installation and operator training

-

Preventative maintenance and service support

-

Guidance on automated sampling integration for high-volume operations