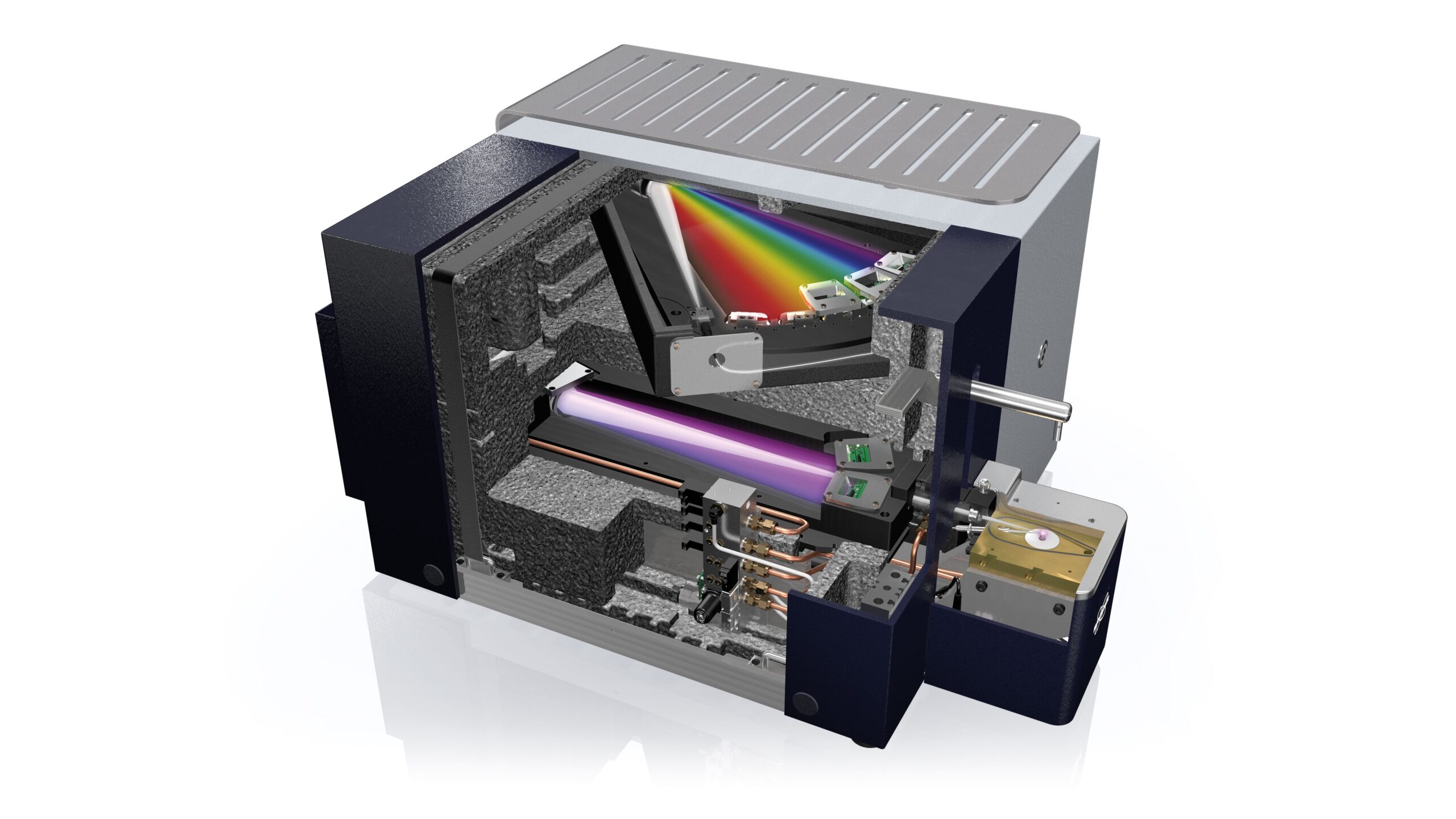

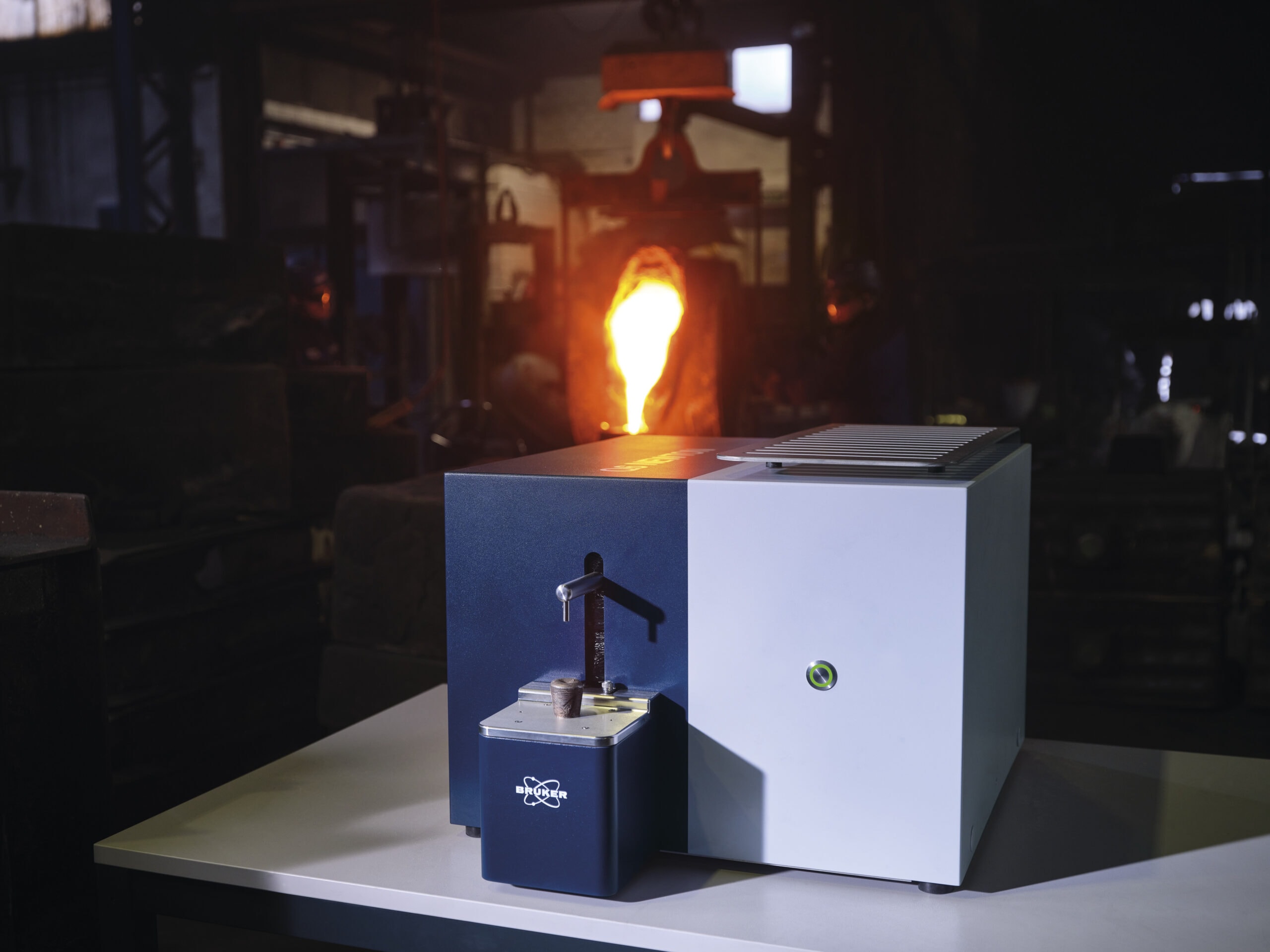

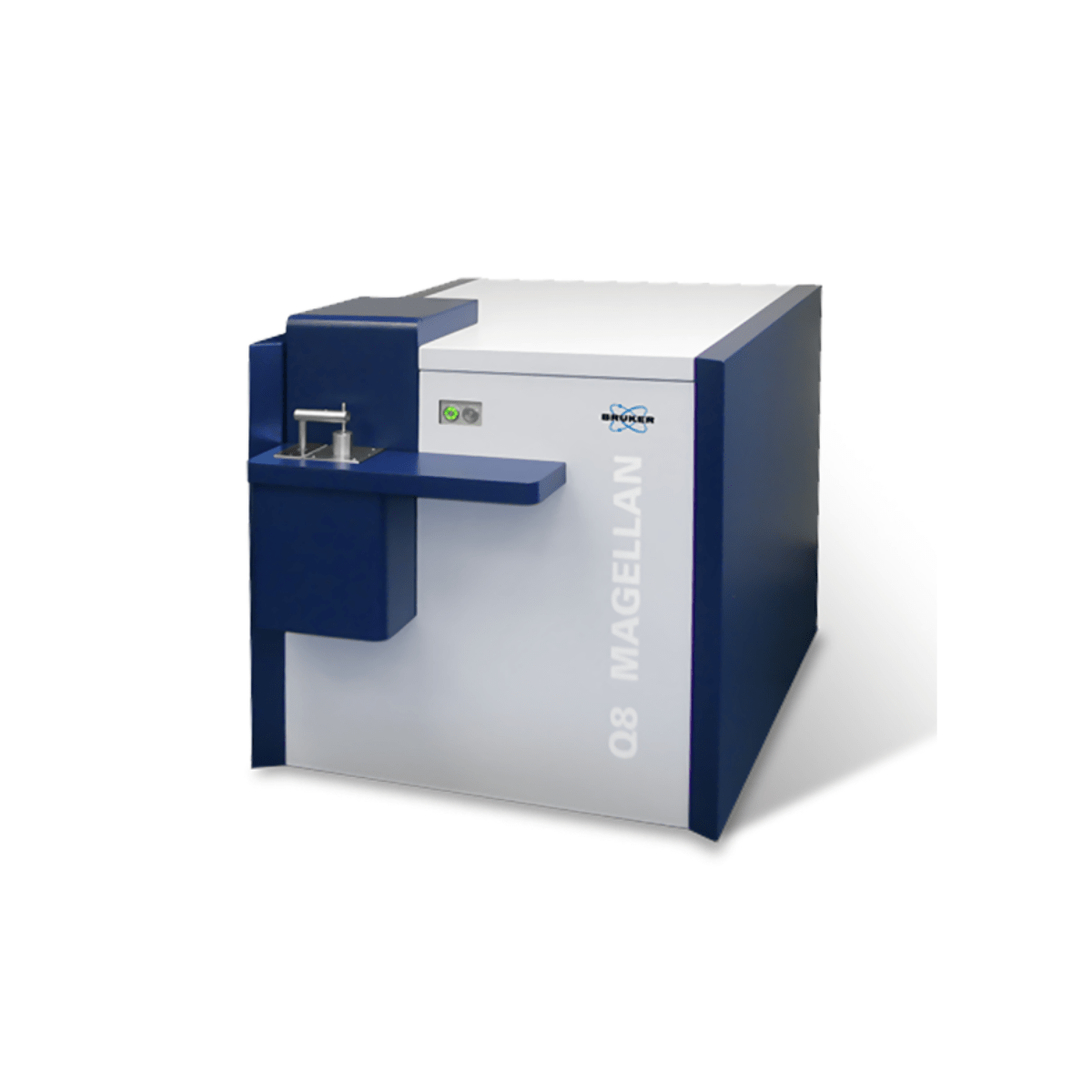

The Bruker Q6 NEWTON is a fixed benchtop spark OES instrument designed for metal producers and QA laboratories that need fast, stable compositional data across ferrous and non-ferrous alloys. The system uses CMOS detectors and a temperature-controlled optical bench to maintain repeatability during routine checks, melt corrections or batch release.

The dual-optic layout allows simultaneous measurement of high-energy emission lines – including nitrogen, phosphorus and oxygen alongside standard alloying and residual elements. This is relevant for steelmaking, aluminium cast houses, copper refineries and titanium processing, where specific trace elements influence mechanical properties and downstream processing.

Argon flow is regulated to protect the optical path and reduce overall consumption. Routine access to the spark stand and internal assemblies keeps maintenance straightforward for production environments.

This configuration suits facilities that cannot afford long warm-up periods, require predictable drift behaviour and run multi-matrix workloads under a central QC/QA programme.

Applications

1. Steel and Cast Iron Production

Used for melt corrections, furnace adjustments and release testing. Supports nitrogen, carbon, phosphorus, sulphur and alloying/residual elements required for steel specification checks.

2. Aluminium Casthouses and Rolling Mills

Monitors P, Na, Li and alkali elements that affect casting, extrusion and rolling performance. Suitable for verifying chemistry during batch corrections and final QC.

3. Copper and Copper-Alloy Processing

Measures brasses, bronzes and high-conductivity grades, including low-level oxygen where conductivity and mechanical behaviour are sensitive to trace variations.

4. Titanium and High-Integrity Alloys

Used to confirm chemistry for aerospace, defence and medical-grade titanium, where deviations in oxygen, nitrogen or alloy balance are not tolerated.

5. General Non-Ferrous Alloys

Suitable for zinc-, magnesium-, nickel-, tin- and cobalt-based alloys across casting, machining and finishing workflows.

6. Central QC/QA Laboratories

Fits multi-matrix testing environments that support production, incoming inspection and certification. Provides consistent turnaround for routine QC and audit-driven reporting.

Labquip NDT Support

- Labquip NDT supplies and supports the Bruker Q6 NEWTON across the UK.

- Our team provides guidance on instrument configuration for your alloy ranges and QC/QA workflows, supports integration with existing reporting systems and offers operator training for production, warehouse and laboratory staff.

- We also provide ongoing service and maintenance to keep the spectrometer operating within specification over its working life.