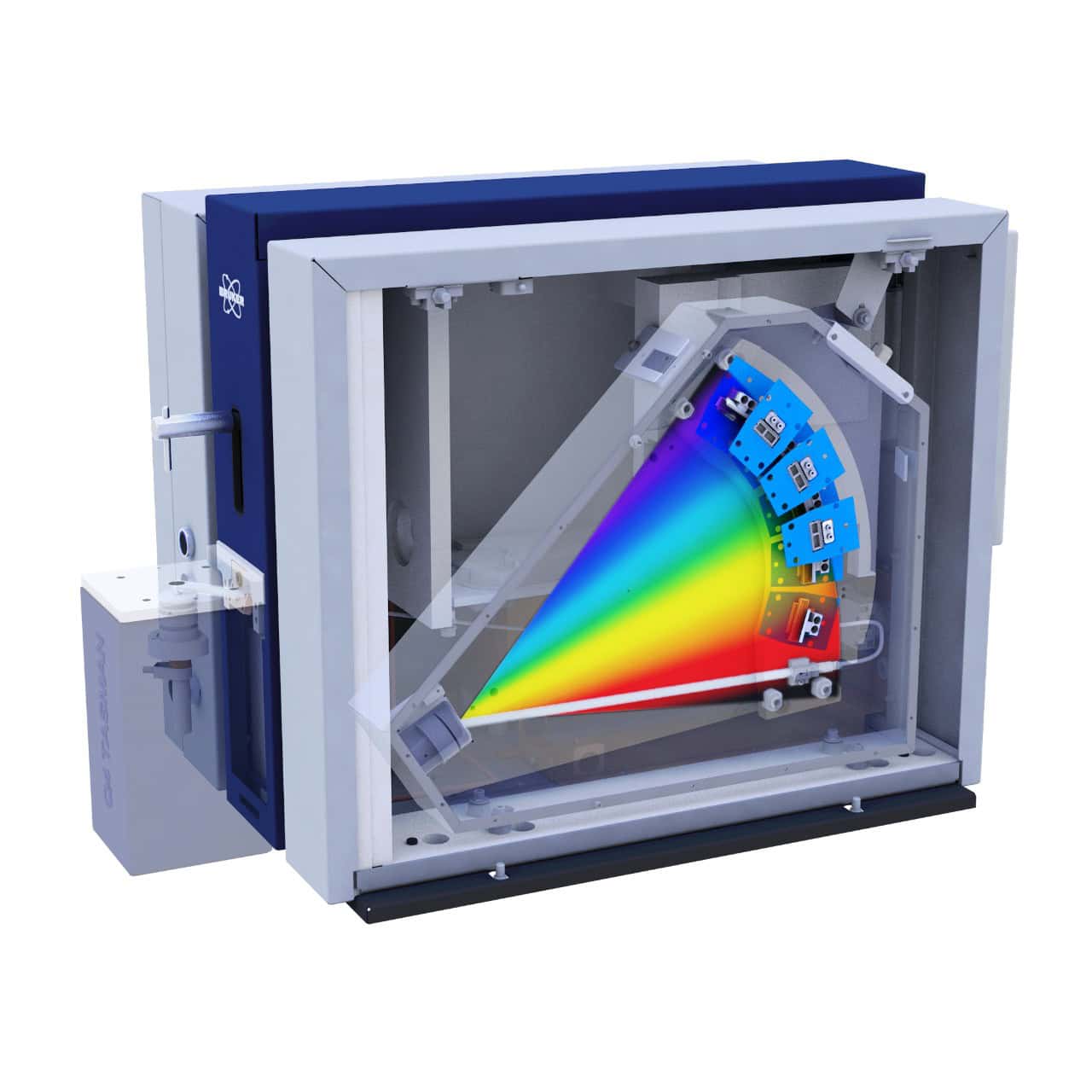

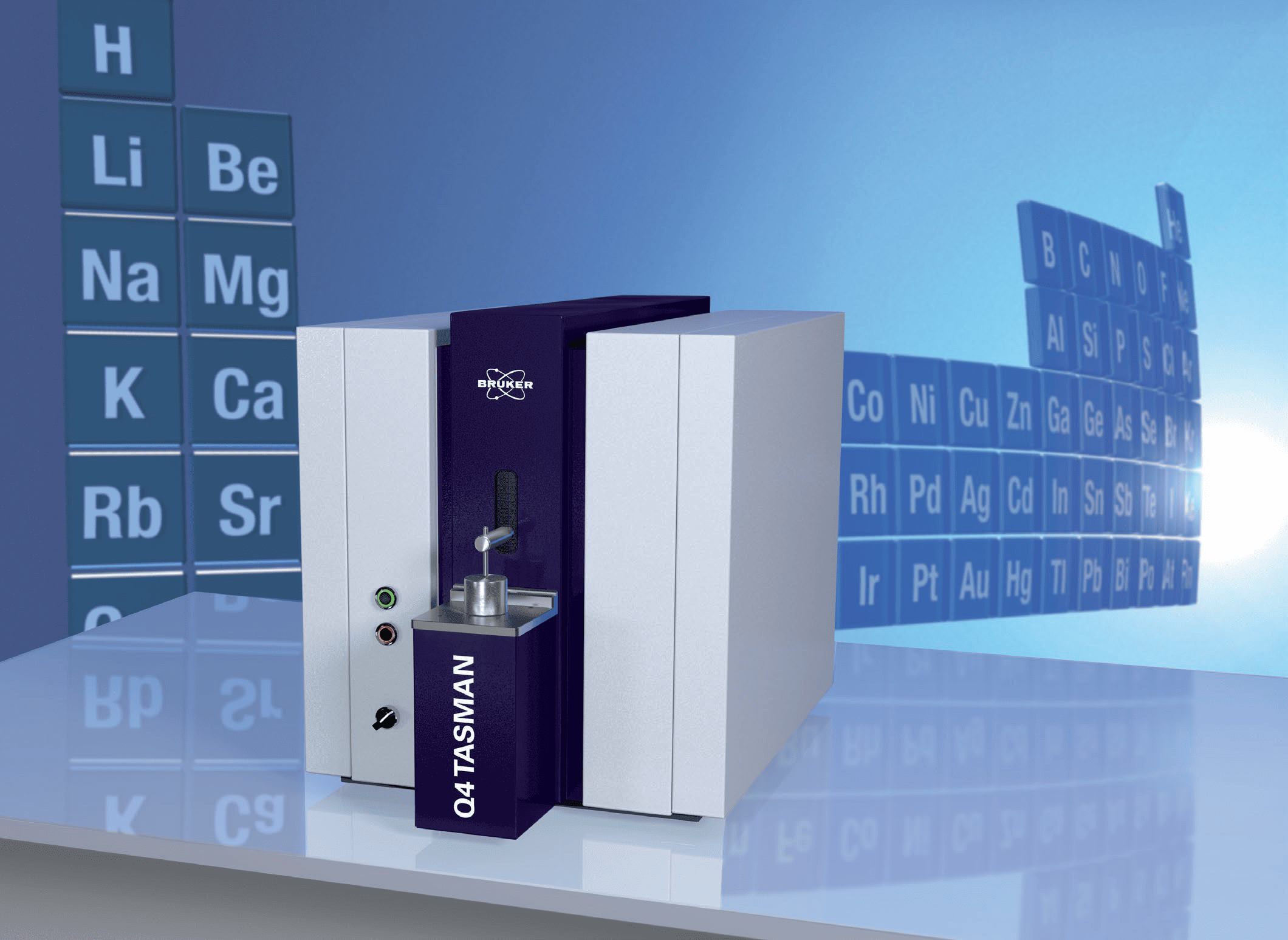

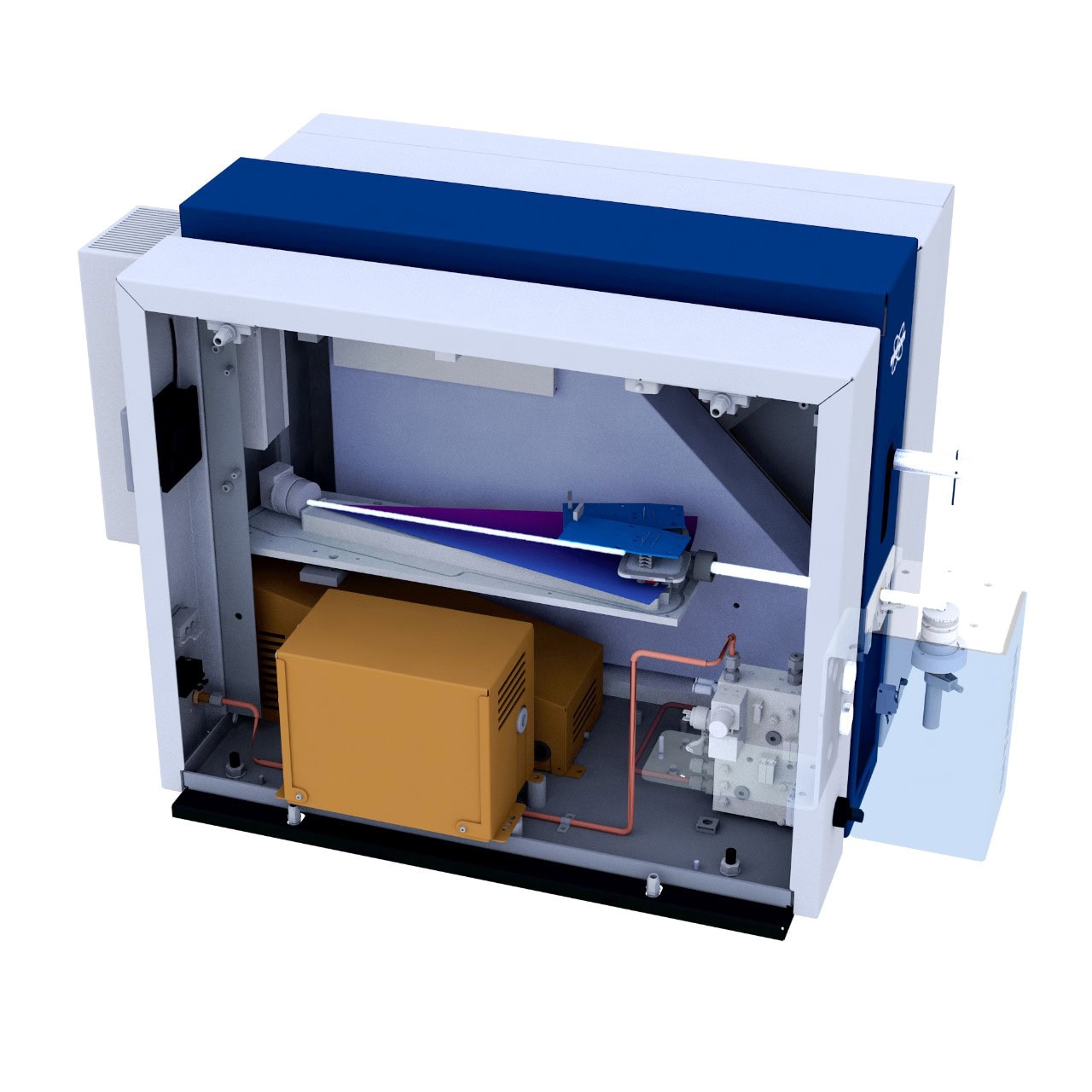

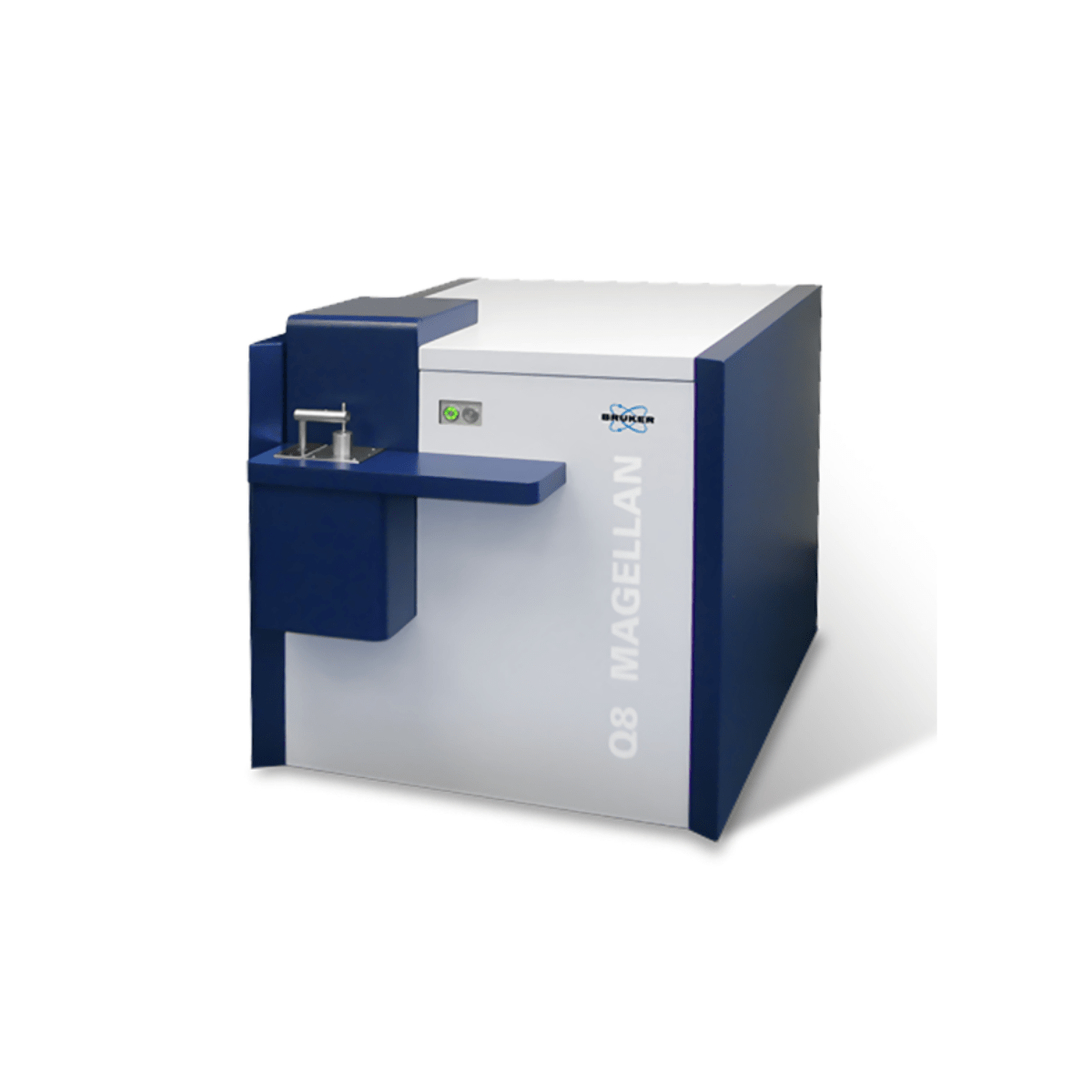

The Q4 TASMAN Series 2 is a configurable benchtop spark OES platform designed for laboratories and production facilities that handle mixed alloy ranges. The optical system can be tailored to specific process needs from high-resolution nitrogen analysis in steels to broad multi-matrix work in foundries and recycling plants.

The dual-optic options extend the measurable wavelength range for applications that require both deep UV and visible-region lines, enabling accurate control of light elements, alloying additions and residuals. Stability enhancements in the Series 2 platform reduce drift over long shifts, making it suitable for production environments with variable temperatures.

The TASMAN Series 2 is often selected by QC labs that require a scalable OES system: compact enough for bench installation, but powerful enough to support full-process melt control, incoming inspection and batch release across ferrous and non-ferrous metals.

Applications

1. Iron & Steel – Melt Control & Residual Element Monitoring

Used to control carbon, sulphur, phosphorus, nitrogen, alloy additions and tramp elements in foundries, steelworks and component production.

2. Aluminium – Alloy Chemistry Control

Measures phosphorus, alkalis and alloying additions relevant to casting, extrusion and rolling processes.

3. Copper & Copper Alloys

Suitable for brasses, bronzes and oxygen-sensitive copper grades requiring trace-level oxygen and impurity control.

4. Titanium & High-Performance Alloys

Supports aerospace, defence and medical sectors with tight composition tolerances and multi-element trace requirements.

5. Non-Ferrous & Specialty Metals

Covers Pb, Sn, Zn, Co, Ni and Mg applications found in recycling, die-casting, machining and general alloy production.

Labquip NDT Support

-

Configuration guidance based on application and alloy range

-

Installation, commissioning and operator training

-

In house preventative maintenance services