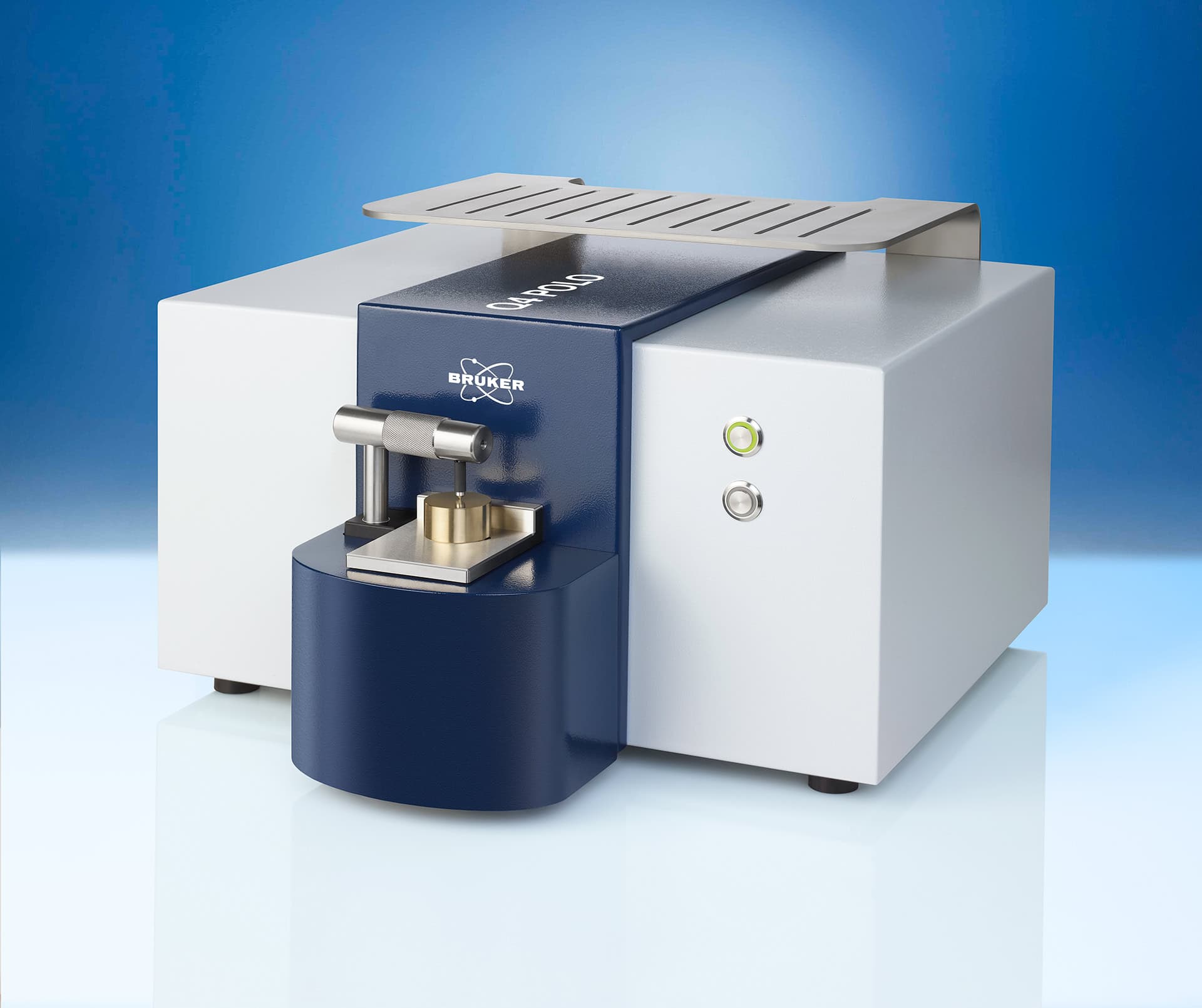

The Bruker Q4 POLO is a compact benchtop spark OES spectrometer designed for routine metals inspection where fast turnaround and consistent repeatability matter. It provides complete elemental coverage — including light elements and trace residuals — for steels, cast irons, aluminium, copper and general non-ferrous alloys.

The optical system spans 130–785 nm, allowing technicians to measure the emission lines needed for melt corrections, batch release, incoming material checks and recycled feedstock sorting. Temperature-compensated optics reduce drift across long shifts, and the argon-protected window helps the system maintain stable calibration in typical foundry and production environments.

Its footprint makes it suitable for smaller labs or direct shop-floor placement, offering the analytical capability of a larger OES system without the space or utility demands.

Applications

1. Iron & Steel — Melt Control / Batch Release

Used for carbon, sulphur, phosphorus, nitrogen, alloying elements and trace residuals essential for foundry and steelworks QC.

2. Aluminium Production — Alloy Chemistry Control

Measures phosphorus, alkalis and light elements affecting casting properties and process consistency in casthouses and rolling plants.

3. Copper & Copper Alloys — Composition and Oxygen Levels

Suitable for brasses, bronzes and high-conductivity copper grades, including low-level oxygen where electrical and mechanical properties depend on precise trace control.

4. Foundries – Routine Quality Control

Supports melt corrections, charge checks and final inspection of cast components against customer specifications.

5. Metal Recycling – Feedstock Verification

Enables accurate sorting and grading of recycled materials, detecting contaminants and residuals that influence melt quality.

6. General QC/QA – Multi-Matrix Workloads

Fits production labs that test ferrous and non-ferrous alloys for incoming inspection, process checks, and certification.

Labquip NDT Support

Labquip NDT provides full support across the UK for the Q4 POLO, including:

-

Advice on configuration based on your alloy range and workflow

-

Installation and operator training

-

Preventative maintenance

-

Support for routine QC setup and grade verification