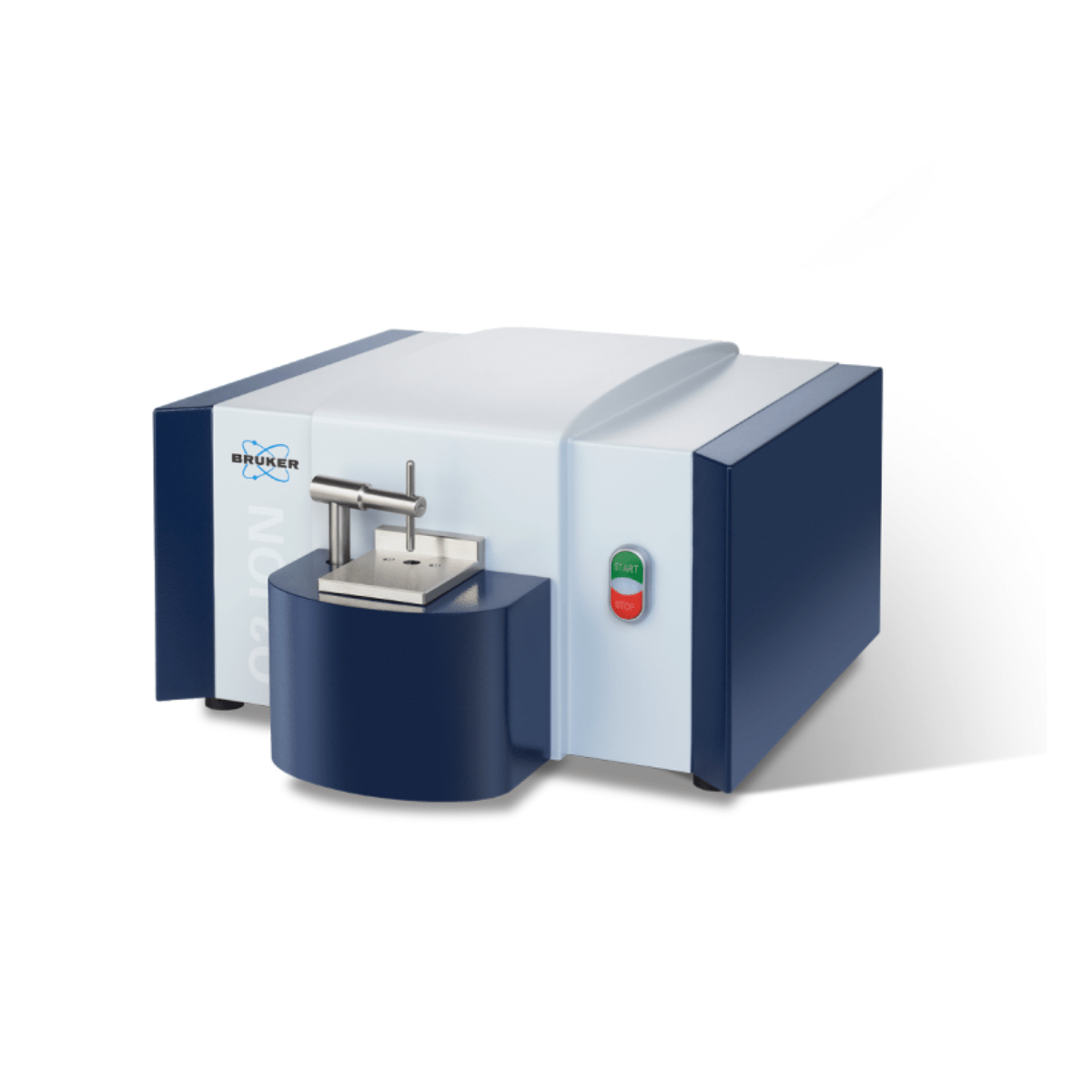

The Bruker Q2 ION is a portable spark OES system – one of the lightest spark spectrometers on the market, weighing only 19 kg. It’s built for production teams, fabricators, and metal recyclers who need fast alloy verification without the footprint of a floor-standing OES.

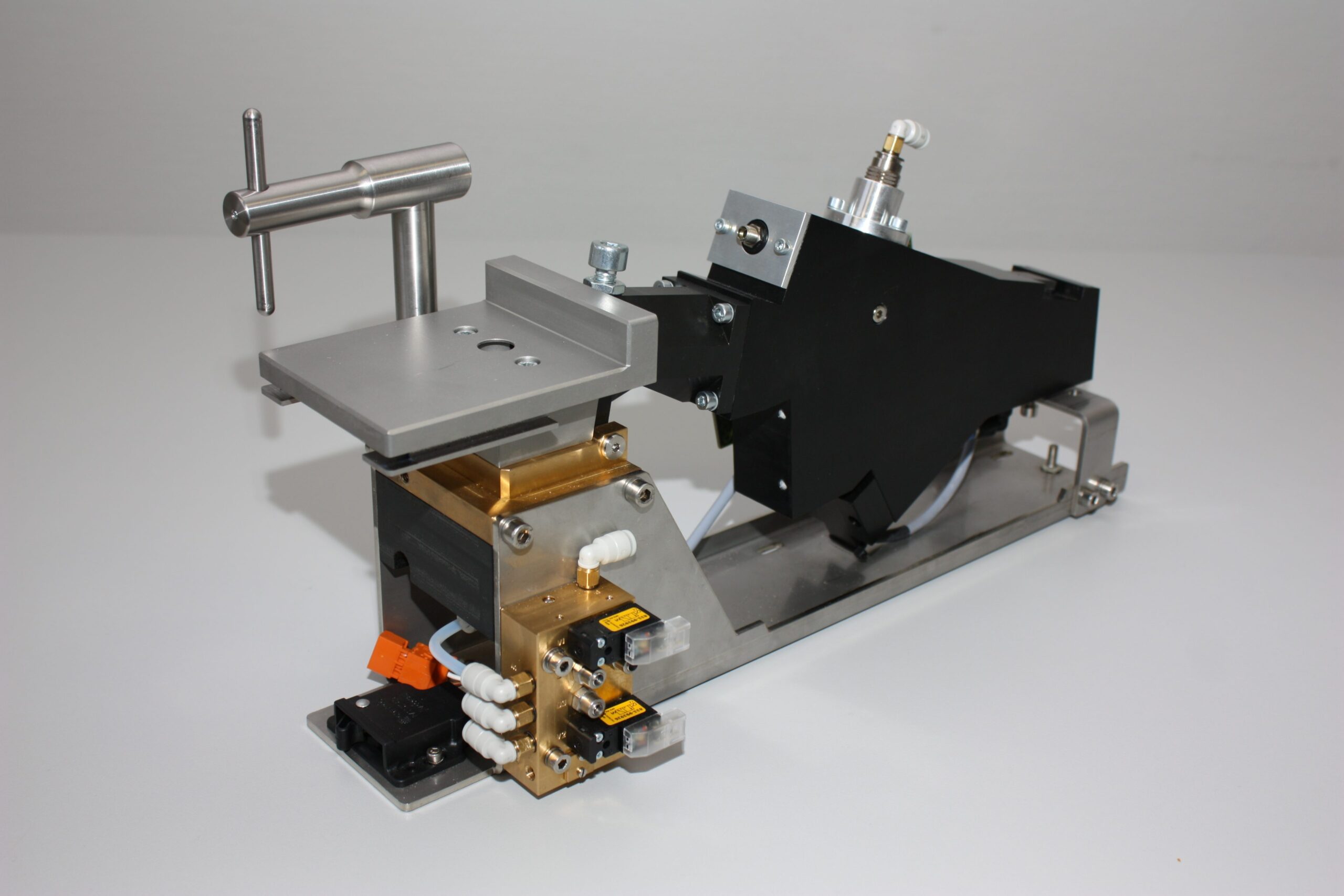

The system is straightforward: place the sample on the spark stand and get a full chemistry result in under 30 seconds. Its flat-field CCD optics and Active Ambient Compensation maintain stability between 10–45 °C, so results remain consistent across workshops, QA labs, and semi-mobile setups.

The analyser runs on low argon flow, keeps maintenance to a minimum, and uses Bruker’s ELEMENTAL.SUITE software — simple menus, controlled user access, and smooth export to Excel or QC systems.

For many customers, the Q2 ION offers a practical alternative to larger OES units. It supports steel, aluminium, copper, nickel, and other common alloys, making it suited to incoming material checks, grade verification, and routine QA work.

Applications

1. Foundries & Melt Shops – Melt and Charge Control

Used for melt checks before casting, verification of charge materials and monitoring of tramp elements (e.g. P, S, Cu, Sn) in cast irons, steels, aluminium and copper alloys. Supports production QC at the furnace and during batch release.

2. Metal Processing & Fabrication – Material Compliance & Traceability

Confirms alloy chemistry during fabrication, machining and welding to ensure material compliance with EN/ASTM specifications. Helps QA teams prevent non-conforming material entering production or leaving the factory.

3. Quality Control & QA Laboratories – Routine Alloy Verification

Deployed in QC labs to check that heats, batches and incoming materials match their specification. Suitable for measuring key elements such as C, P, S, Cr, Ni, Mo, Al, Cu, Sn and other residuals for release testing, documentation and audits.

4. Incoming Material Inspection – Verifying Certificates and Stock

Checks supplier certificates against actual composition and identifies mixed or mislabelled material before it reaches machining, welding or assembly. Reduces rework and delays caused by incorrect stock.

5. Warehousing & Stock Management – Avoiding Alloy Mix-Ups

Supports fast identification of stored bars, billets, plates and components during receiving, inventory and dispatch. Helps stockholders and fabrication shops keep alloy families separated and correctly labelled.

6. Recycling & Scrap Sorting – Feedstock Quality Control

Used to classify ferrous and non-ferrous scrap and to check residual elements that may affect melt quality, furnace balance or mechanical properties of the final product.

7. Inspection & Testing Services – Third-Party Metals Analysis

Suitable for inspection companies and test houses that provide independent verification of steels, Ni-alloys, Al-alloys, Cu-alloys and cast irons across multiple sites and customer locations.

Labquip NDT Support

- Labquip NDT supplies and supports the Bruker Q2 ION across the UK.

- Our team provides guidance on instrument configuration for your alloy ranges and QC/QA workflows, supports integration with existing reporting systems and offers operator training for production, warehouse and laboratory staff.

- We also provide ongoing service and maintenance to keep the spectrometer operating within specification over its working life.