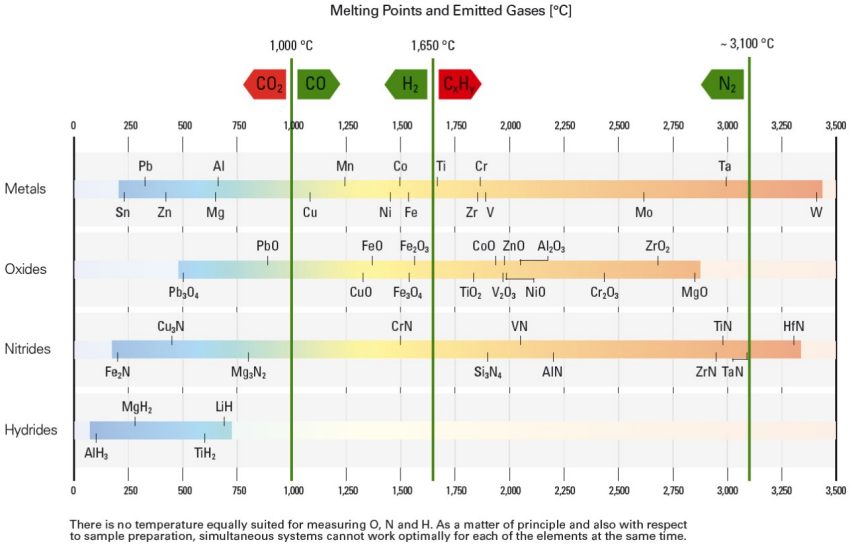

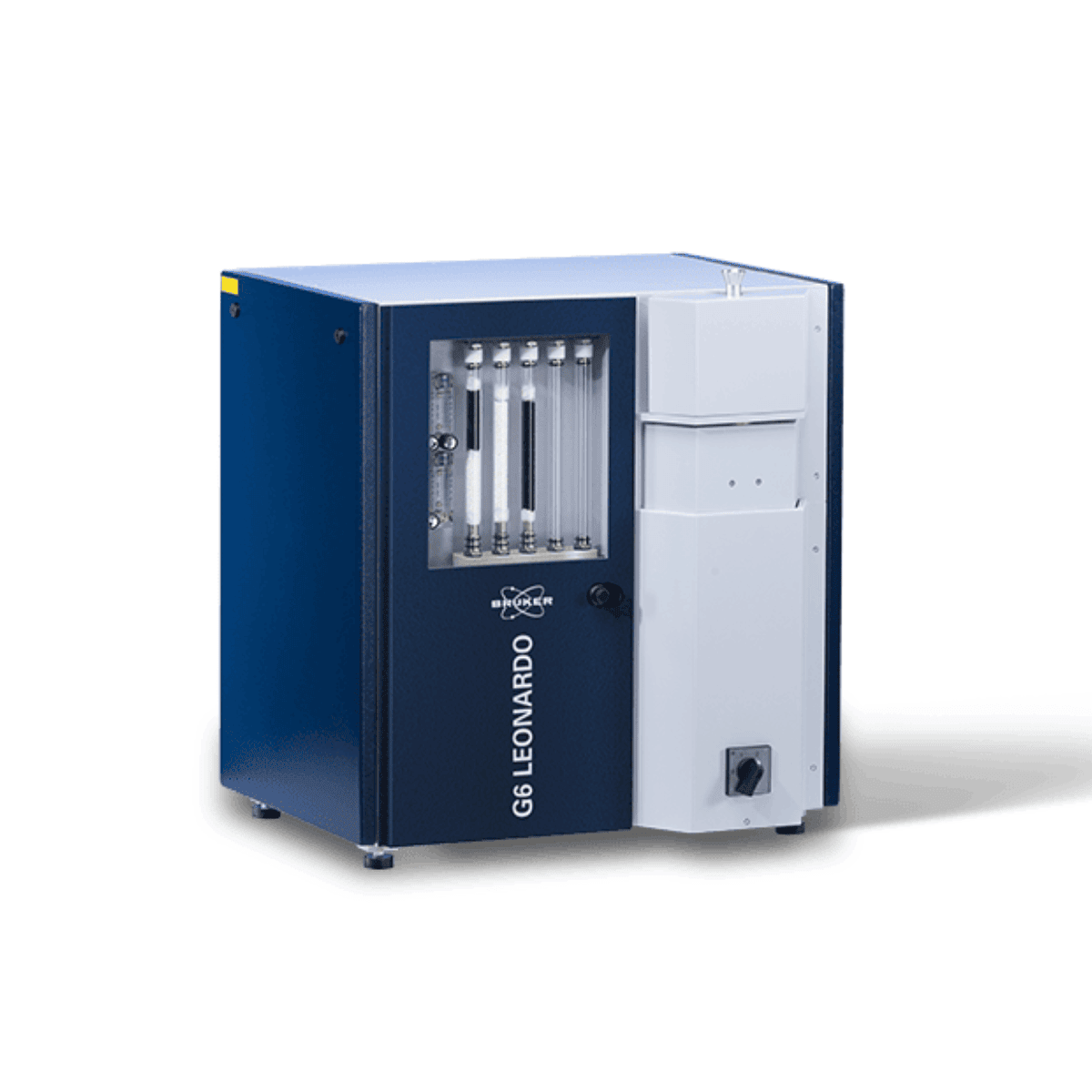

The Bruker G8 GALILEO is a floor-standing inert gas fusion analyser designed for precise determination of oxygen (O), nitrogen (N) and hydrogen (H) in metals, alloys, powders and ceramic materials. With a large furnace capacity, automated handling, multi-detector options and advanced process monitoring, it is engineered for laboratories that demand maximum analytical stability, high throughput and ultra-low detection limits.

Labs choose the G8 GALILEO when they require research-grade ONH accuracy or when analysing materials where trace gas levels determine mechanical integrity, microstructure quality or failure risk. The mass spectrometer option extends sensitivity into the sub-ppm and ppb range, supporting applications such as high-purity metals, speciality alloys, hydrogen-sensitive materials and advanced R&D programs.

With its floor-standing architecture and automated handling, the G8 GALILEO is suited to high-volume ONH analysis in steel mills, powder plants and aerospace materials labs where trace-gas accuracy and multi-material flexibility are essential.

Applications

1. Steel, Iron & High-Performance Alloys

Precise oxygen and nitrogen measurement for melt control, secondary metallurgy and final product certification. Suitable for carbon steels, stainless steels, tool steels, nickel, cobalt and ferroalloys, where O/N levels directly influence toughness, cleanliness and fatigue performance.

2. Copper, Aluminium & Magnesium Production

Hydrogen and oxygen analysis to prevent hydrogen embrittlement, porosity, oxide inclusions and casting defects. Supports grading of copper cathodes, cast products, rolled aluminium and magnesium alloys.

3. Titanium, Zirconium & Reactive Metals

Strict control of O/N/H in aerospace, defence and medical-grade alloys. Essential for materials with tight impurity tolerances and high sensitivity to hydrogen pick-up.

4. Additive Manufacturing & Powder Metallurgy

ONH analysis of metal powders used in laser powder bed fusion (LPBF), binder jetting and MIM processes. Helps verify powder purity, monitor powder reuse and maintain consistent component density and microstructure.

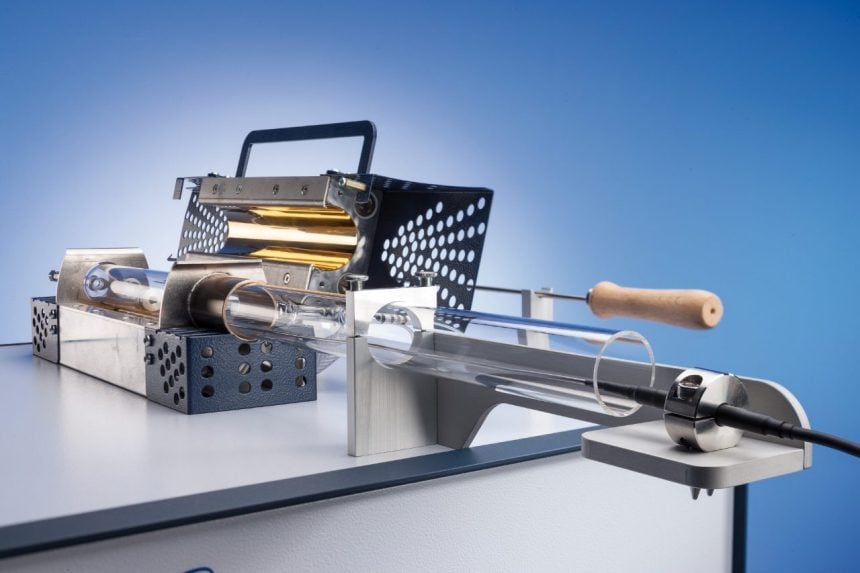

5. Welding, Fabrication & Diffusible Hydrogen Testing

Supports weld qualification and hydrogen control according to ISO 3690 / AWS A4.3 when equipped with the external IR furnace. Ensures weld integrity and reduces the risk of cold cracking and delayed hydrogen fracture.

6. Glass, Ceramics & Refractory Materials

ONH measurement in oxide materials, nitrides, carbides and high-temperature ceramics used in refractories, electronics and advanced structural applications.

Labquip NDT Support

Labquip NDT provides full support for Bruker ONH analysers across the UK:

-

Application guidance based on your material types, ONH ranges and workflow

-

Installation, commissioning and operator training for industrial and R&D laboratories

-

Support with calibration gases, reference materials and method optimisation

-

Local after-sales support, troubleshooting and service coordination for reliable ongoing operation