The Bruker G6 LEONARDO is a benchtop inert gas fusion (IGF) analyser designed for accurate and repeatable measurement of oxygen (O), nitrogen (N) and hydrogen (H) in metals, alloys, ceramics and high-purity powders. Built around FusionControl™, SampleCare™ and Smart Molecule Sequence™ technologies, the system provides stable furnace performance, controlled sample handling and direct gas quantification ensuring reliable ONH results across a wide range of materials.

Labs select the G6 LEONARDO when they require precise O/N/H quality control during melting, casting, powder production or material qualification. Its compact footprint, low gas consumption and minimal maintenance demands make it suitable for routine QC, incoming inspection and process monitoring. For users working in metal manufacturing, powder metallurgy or ceramics, the analyser offers a cost-effective and repeatable method for determining trace gas levels that directly influence mechanical properties, corrosion behaviour, porosity and product performance.

Applications

1. Iron, Steel & Ferroalloy Production

Measurement of oxygen and nitrogen for melt control, ladle treatment verification and final quality certification in steels, stainless steels, tool steels, nickel- and cobalt-based alloys. Helps prevent brittleness, inclusions and porosity linked to elevated O/N levels.

2. Copper & Copper Alloys

Determination of hydrogen and oxygen to avoid steam blistering, porosity and hydrogen embrittlement. Supports QC in copper casting, tube manufacturing and electrical-grade materials.

3. Titanium, Zirconium & Reactive Alloys

Strict O/N/H control for aerospace, medical and defence-grade materials, where gas pickup affects ductility, fatigue resistance and structural integrity. Suitable for sponge, ingots, bars and powder feedstocks.

4. Aluminium & Magnesium Production

Measurement of dissolved hydrogen and oxygen to reduce gas porosity, inclusions and casting defects. Supports foundries, rolling mills and extrusion operations.

5. Powder Metallurgy & Additive Manufacturing (AM)

O/N/H analysis in metal powders, including steels, Ti alloys, Ni alloys and aluminium powders. Monitors oxidation and moisture pickup, supports powder reuse strategies, and maintains repeatable density and microstructure in AM builds.

6. Ceramics, Glass & Refractory Materials

ONH quantification in technical ceramics, glass, refractories, oxide materials and sintered components for process control and long-term stability in demanding thermal environments.

Labquip NDT Support

Labquip NDT provides full support for Bruker ONH analysers across the UK, offering:

-

Application advice based on your material type, required detection limits and workflow

-

Installation, commissioning and operator training for industrial and research laboratories

-

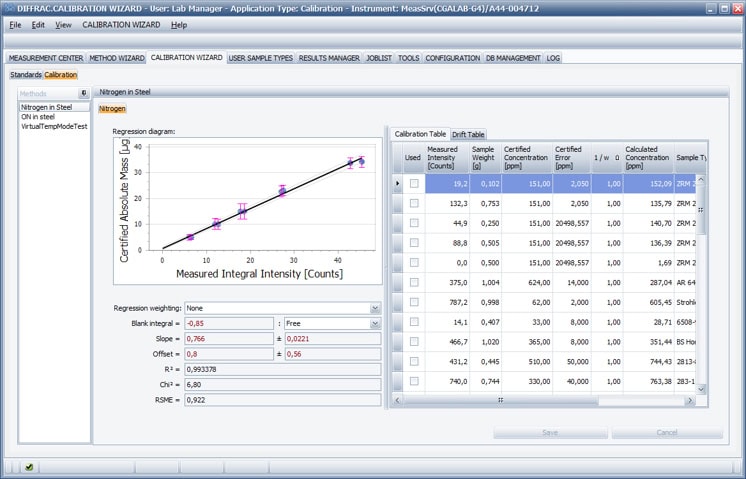

Assistance with calibration routines, reference materials and method setup to ensure accurate ONH results

-

Local after-sales support, troubleshooting and service coordination for dependable long-term operation