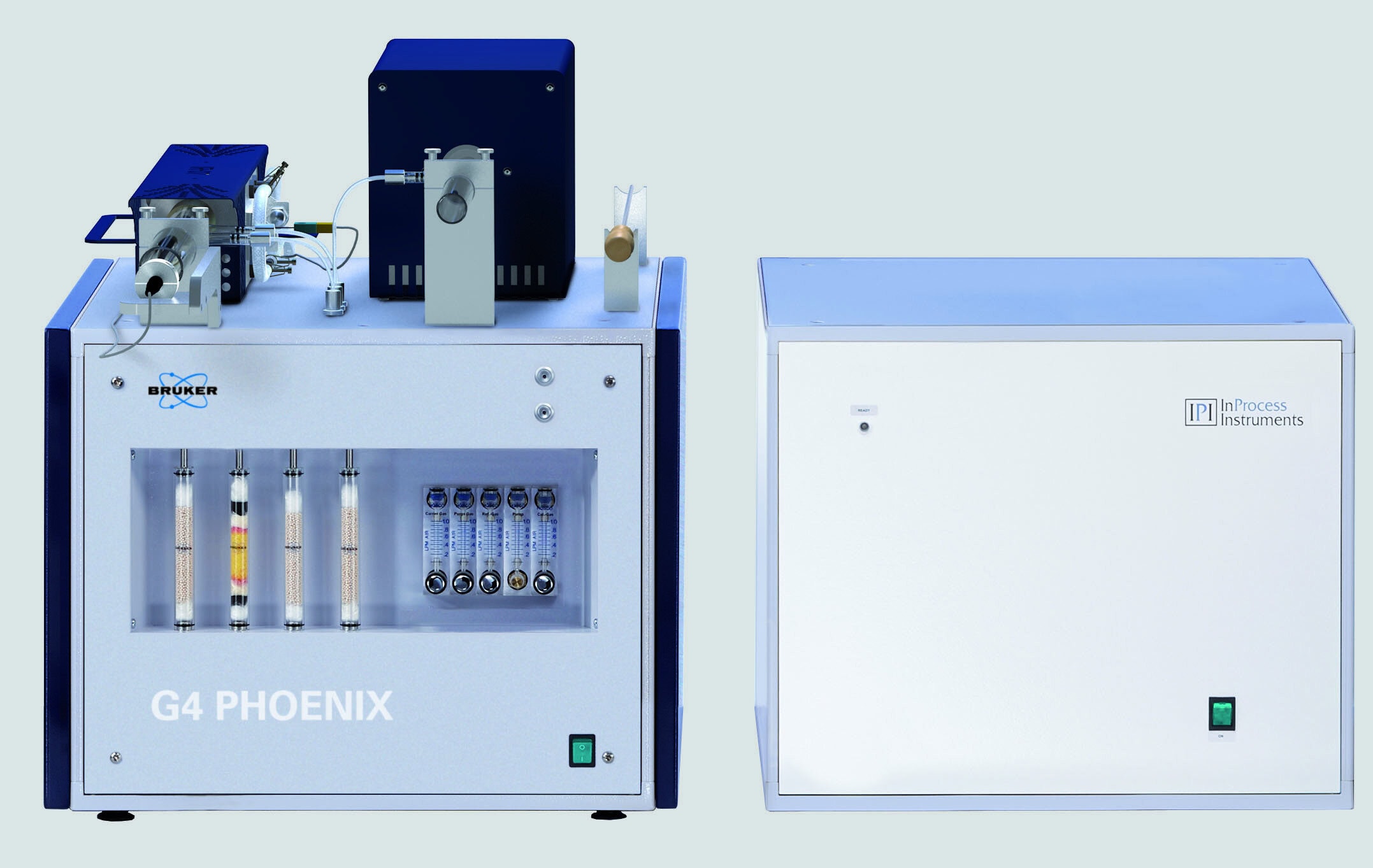

The Bruker G4 PHOENIX DH is a benchtop diffusible hydrogen analyser developed for fast, accurate hydrogen determination in welded joints, high-strength steels and other materials where hydrogen embrittlement is a critical risk. Using warm extraction with an infrared or resistance furnace, it delivers quantitative hydrogen results in under 30 minutes.

Labs choose the PHOENIX DH when their workflow requires traceable diffusible hydrogen measurement for weld qualification (ISO 3690 / AWS A4.3) or when controlling post-weld hydrogen is essential to avoid cracking. The system is also used in alloy development and research where hydrogen trapping, diffusion behaviour or desorption profiles need to be characterised. With sub-ppm sensitivity from the TCD detector and optional mass spectrometry for ultra-low concentration work, the analyser delivers stable, repeatable hydrogen measurements across a wide range of metallic materials.

This combination of speed, accuracy and matrix flexibility makes the PHOENIX DH suitable for welding laboratories, steel producers, automotive and aerospace suppliers, and materials research facilities working to mitigate hydrogen-related failures.

Applications

1. Welding & Fabrication

-

Diffusible hydrogen measurement according to ISO 3690 / AWS A4.3

-

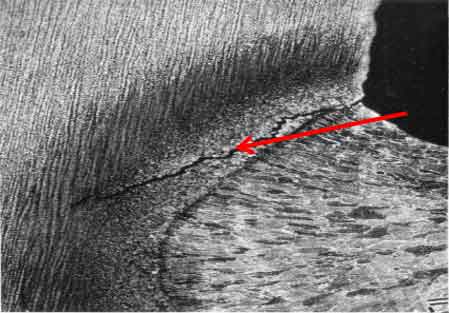

Prevents hydrogen-induced cracking (HIC/HAC) and delayed cracking

-

Suitable for weld seams, repaired welds, procedure qualification and test plates

2. High-Strength & Advanced Structural Alloys

-

Quantifying hydrogen to prevent embrittlement in AHSS, quenched & tempered steels, and structural steels

-

Used in automotive safety components, offshore structures, and cold-formed steel parts

3. Materials Research & Alloy Development

-

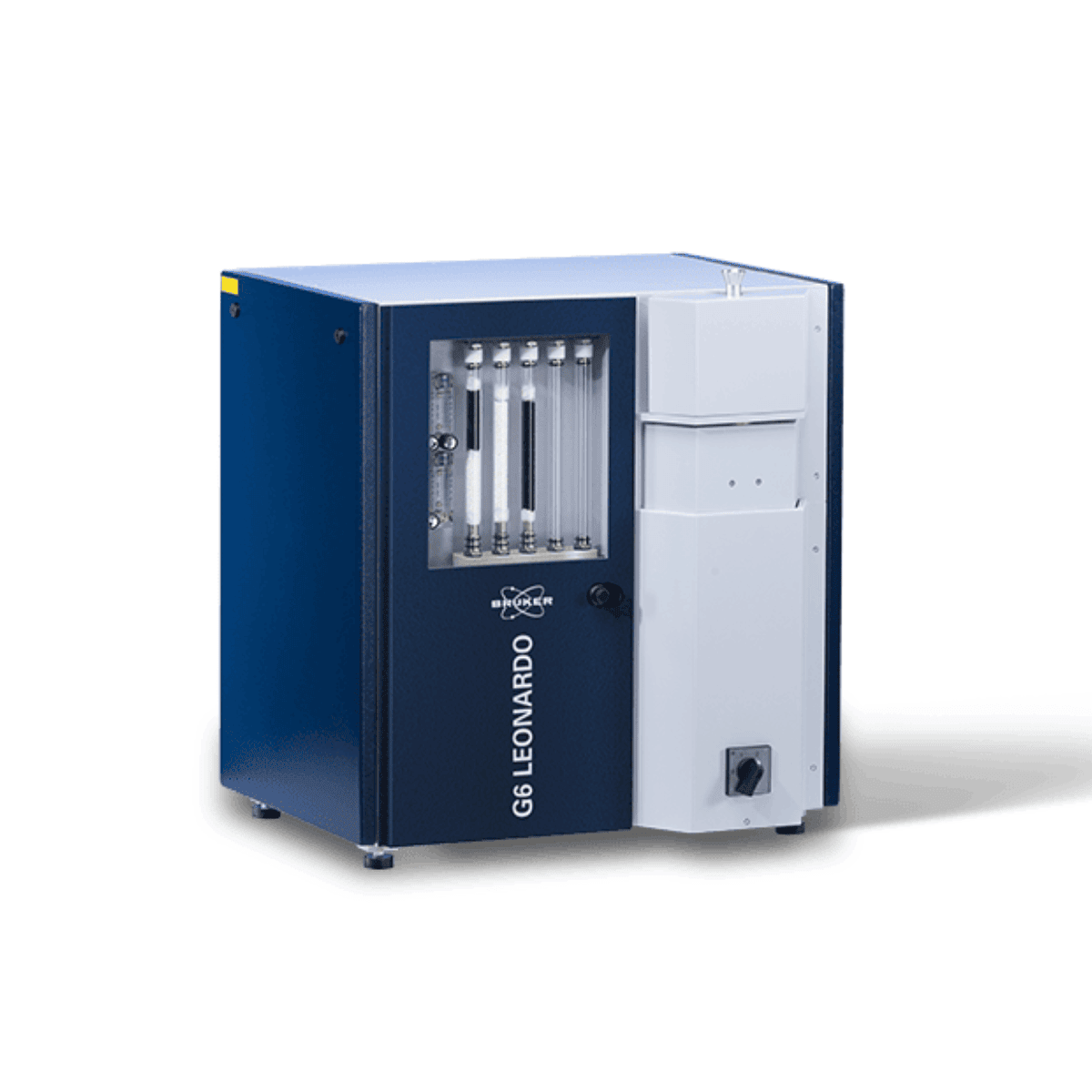

Thermal Desorption Mass Spectrometry (TDMS) for hydrogen trapping, desorption kinetics and isotopic analysis

-

Supports alloy development for hydrogen resistance and hydrogen storage research

4. Automotive & Aerospace Engineering

-

Ensures hydrogen resistance in high-performance steels, nickel alloys and welded assemblies

-

Critical for safety components exposed to stress and environmental humidity

5. Hydrogen Uptake During Manufacturing Processes

- Hydrogen can be introduced during galvanic and electroplating operations, heat treatment, stamping, forming, thermal processing, coating, machining, grinding, soldering and brazing. These steps can significantly increase the risk of hydrogen-induced cracking in susceptible alloys.

- Applications include coated steels (galvanized, electroplated), formed automotive panels, bent structural sections, forgings and other components exposed to mechanical or thermal processing.

6. General Metallic Materials

-

Suitable for steels, cast iron, copper alloys, duplex steels, and multi-phase materials

-

Enables routine QC, hydrogen monitoring, and process optimisation

Labquip NDT Support

Labquip NDT supports Bruker hydrogen analysers across the UK with:

-

Application guidance based on sample type, extraction temperature and standards

-

Installation, commissioning and operator training for welding labs and materials departments

-

Assistance with calibration routines, reference materials and method optimisation

-

UK-based after-sales support and service coordination for reliable long-term operation