The Bruker G4 ICARUS Series 2 is a benchtop carbon/sulphur (C/S) combustion analyser designed for laboratories that need fast, precise C/S determination in inorganic materials. Its high-frequency induction furnace provides complete combustion in under 60 seconds, supporting high throughput in metal production, foundry control, mineral processing and research environments.

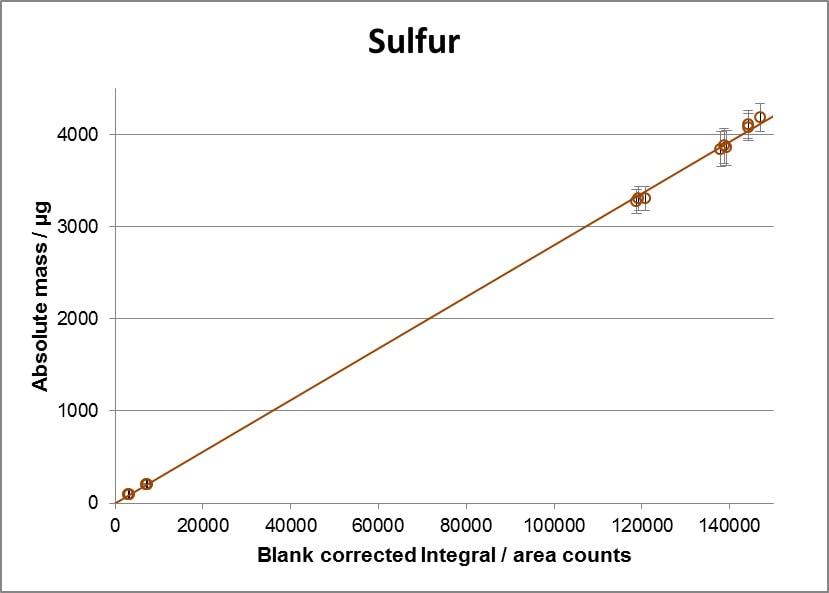

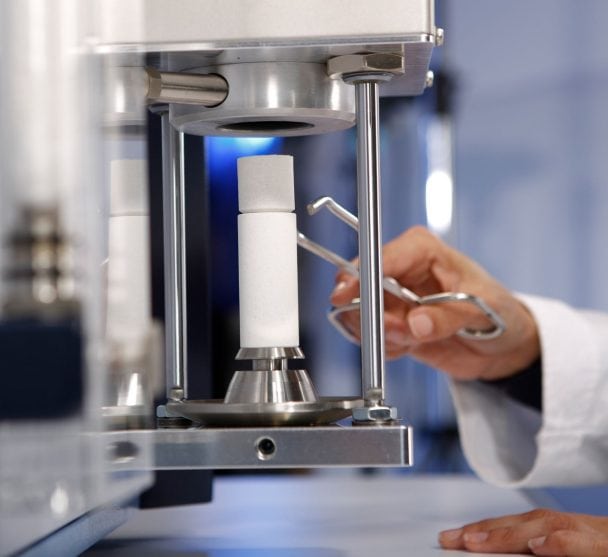

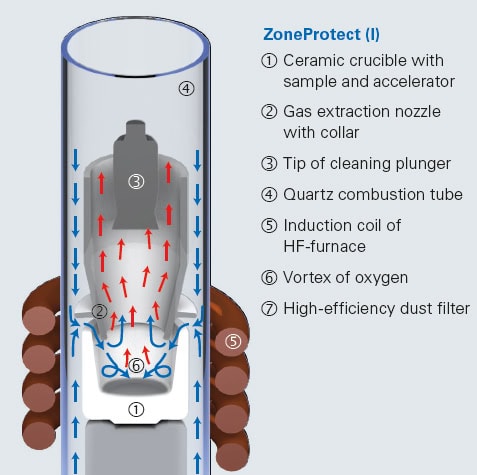

The ZoneProtect™ combustion design maintains stable oxygen flow and keeps the furnace clean, reducing operator intervention and extending the lifetime of combustion tubes. HighSense™ UV-LED detection delivers a stable baseline and improved low-level sulphur performance, while NDIR detectors ensure accurate carbon quantification across a wide dynamic range.

A benchtop C/S system like the G4 ICARUS is typically chosen over larger floor-standing analysers because it delivers complete combustion, short analysis cycles, and highly repeatable results in a compact footprint. Labs benefit from lower infrastructure requirements, easier installation, faster operator training and minimal maintenance routines. The analyser handles both simple and difficult matrices – including graphite-rich cast irons, alloy steels, minerals, ceramics and refractory materials without sacrificing accuracy or stability.

For QA/QC, production control, or materials R&D, the G4 ICARUS Series 2 offers a dependable, straightforward platform for routine C/S analysis with the robustness expected in industrial environments.

Applications

1. Iron & Steel Production

-

Carbon and sulphur control during melt, secondary metallurgy and ladle adjustments

-

Final product certification for steels, stainless steels, tool steels and alloy steels

-

Suitable for integrated steelworks and smaller melt shops

2. Cast Iron (Grey, Ductile, CGI)

-

Accurate C/S measurement in graphite-rich matrices

-

Supports routine QC for automotive castings, pump housings, brake components and foundry products

3. Non-Ferrous Metals

-

Carbon/sulphur determination in copper alloys, nickel alloys, cobalt alloys and titanium alloys

-

Useful for aerospace, electronics, and high-temperature alloy production

4. Cement, Limestone & Clinker

-

Monitoring sulphur balance and carbon content in clinker, gypsum, limestone and kiln feed

-

Enables tighter process control in cement manufacturing

5. Mining & Mineral Processing

-

C/S analysis of ores, concentrates, metal sulphides, carbonates and geological samples

-

Supports metallurgical testing, exploration labs and plant optimisation

6. Ceramics, Glass & Refractories

-

Analysis of silica-based ceramics, alumina, zirconia, magnesia and refractory bricks

-

Useful in glass production, furnace linings and advanced ceramics R&D

7. Powders, Industrial Materials & General Inorganics

-

Suitable for ceramic powders, metal powders, catalysts, additives and reference materials

-

Supports quality control and material verification across multiple industries

Labquip NDT Support

Labquip NDT provides support for Bruker C/S combustion analysers across the UK, ensuring your laboratory gets dependable day-to-day performance:

-

Application guidance tailored to your material types, sample preparation, and analytical workflow

-

Installation, commissioning and operator training to get your team running confidently from day one

-

Assistance with reference materials, calibrations and method optimisation for reliable C/S results across different matrices

-

Local after-sales support, service coordination and practical troubleshooting when you need it