Corrosion Mapping with Single-Axis Scanner

In this article:

- Efficient Corrosion Mapping in Confined Spaces: Waygate Technologies developed a single-axis scanner solution for ultrasonic corrosion mapping where two-axis scanners are impractical due to space constraints

- Handheld Scanner with Manual Indexing: The system uses a compact, encoded scanner with manual indexing, ideal for inspecting piping, storage tanks, and other assets prone to internal corrosion and wall loss

- Streamlined Workflow with Mentor UT Integration: The customizable Hand Scanning App on the Mentor UT flaw detector standardizes setup and calibration, reducing technician time and improving inspection consistency

- Optimized for Pitting Corrosion Detection: Featuring a DM Array probe and Palm Scanner, the system ensures consistent coupling pressure and high-resolution imaging for accurate detection of pitting and wall thinning

- Reliable, Repeatable Results for Asset Integrity: The solution enables asset owners to generate detailed corrosion maps efficiently, minimizing reporting delays and improving maintenance planning

Application

Inspection of assets subject to internal corrosion and erosive wall loss such as piping, storage tanks, and other critical assets; requiring mapping and visual display of remaining wall thickness. Hand-held encoded scanner with manual indexing for efficient corrosion inspections.

Modality: Ultrasonic (Phased Array)

Industry: Oil & Gas and Power Generation

Customer need

Single line scans are frequently stitched together to create corrosion maps. This may happen because a two-axis scanner is unavailable or sufficient

space does not exist to properly attach the larger scanner to the asset. Often, this stitching exercise is a cumbersome process that may delay delivery of the final report. The possibility of error is also increased by using an offline stitching process.

Customer solution

By utilising the Manual Indexing feature of Waygate Technologies’ Mentor UT, these maps can be created in real time with a single-axis scanner. Operators simply set up the device as they would a two-axis scanner. After the first line scan of data is collected, the scanner is moved over to the beginning of the 2nd pass. This second line scan of data is collected and mapped in the proper location in real time.

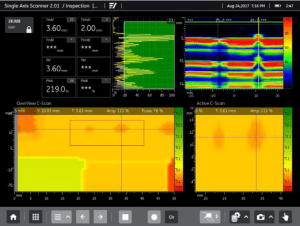

A,C & E Scans, Selectable Measurements, and Touch Screen Operation

Key features

• Customizable Hand Scanning App on the Mentor UT provides a guided workflow to standardize and reduce time for calibration and set-up of inspection

• Touch screen operation for fast and easy interrogation of suspect areas

• DM Array probe optimized for pitting corrosion detection

– Modular probe design for cost effective replacement

• Palm Scanner for consistent coupling pressure during scanning

– Manual indexing for large area inspection scans

Equipment used

• Mentor UT Phased Array Flaw Detector – P/N 100N3883

• DM Acoustic Module (5 MHZ x 1.5 mm) – P/N DMARRAY_MOD1

• Probe Cable (3 m; Side Exit) – P/N DMCABLE_3M_RT

• Palm Flat Scanner with Encoder – P/N 0600176

• Encoder Adapter for Mentor UT – P/N 0600185