Brukers’ pXRF – The Answers in Hand

Labquip NDT using the Bruker S1 Titan XRF to test for POPs at one of the UK’s Local MRFs (Material Recycling Facility)

Right now, nearly all manufacturing businesses and local authorities in the non destructive testing (NDT) or elemental analysis could use at least one of Bruker’s portable XRF material analysis units in their day-to-day operations. The reason?

Bruker handheld technology gives answers in seconds to multivarious questions of legality, environmental standards; planning procedures; analysis of incoming materials, analysis of recyclate and post-industrial and post-consumer waste. A new handheld breakthrough in soil analysis has also been announced by the equipment giant.

In the UK, for example, legislation now requires the speedy identification, treatment and disposal of persistent organic pollutants (POPs) in various waste streams; from textiles and furniture to electrical and consumer goods. These regulations became law some two years ago; will be monitored and policed by UK local authorities and will be enforced by the UK national Environmental Agencies.

Chris Vaughan of Labquip NDT UK says that ‘we know that many waste contractors are struggling to keep up with the pace of events, and also struggling to find ways and means to effectively identify these contaminants without spending a fortune on laboratories and scientific services.’

The new UK laws – mirrored elsewhere in Europe – set extremely precise parameters for the allowable levels of POPs in waste streams. The sampling and measurement of such waste streams needs to be as precise as possible. Chris says that X ray fluorescent analysis (XRF) is therefore the way forward – and that the solution needs to be portable.

‘These issues need to be dealt with on site and in-situ,’ he says. ‘Waste businesses need fast, accurate and precise screening of household waste and other materials.’ And since the new UK regulations are very clear on the permitted trace levels various POP materials, those parameters ideally need to be pre-programmed into whatever identifying technology is being used.

Labquip NDT’s Bruker S1 Titan has settled into effective use a with a number of UK agencies and regulators in the field, prior to further marketing in the waste contracting business.

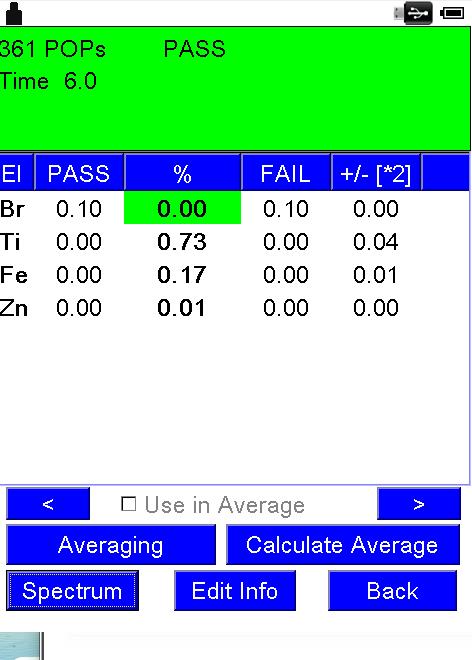

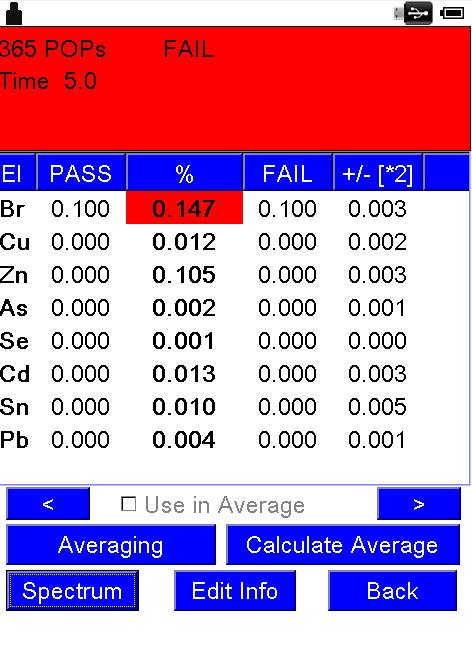

Chris notes that ‘with a press of button the Bruker S1 Titan can scan any part of any waste stream and identify in a second a) which materials and which POPs are present – and to what degree – either in percentages or in parts per million.’

The Bruker S1 Titan also comes pre-loaded with the parameters of the UK’s legislation as part of its extremely user-friendly design. Says Chris; ‘the inbuilt software is actually designed to allow a quick pass/fail mechanism – allowing very quick answers as to whether something is hazardous or not.

UK consumers are likely to encounter the POPS laws when discovering that their waste soft furnishings are not readily recyclable but need to go through new environmental procedures.

However, an even bigger POPS bottleneck is present when it comes to the disposal and recycling of waste electrical and electronic equipment (WEEE) from the general waste stream. Decades of unregulated cheap electrical UK imports from the Far East have created an environmental time bomb in relation to unwanted chemical elements entering water and soil.

Part of the solution to such an environmental time bomb is to encourage the spread of factual and chemical analysis throughout any country’s production, disposal and recycling infrastructure. A comprehensive system of rules for the testing and consistent enforcement on POPS in the waste stream should be established. Government officers and all recycling businesses – not such WEEE based ones – should be subject to the same POPS scrutiny. Better regulation, recording and auditing of recyclers should be established, including a simple pass/fail test of a ‘good’ pellet or regrind in order to prove compliance and continue business.

The accurate, quick and easy functioning of the Bruker S1 Titan is designed to help deliver just that. POP regulations are certainly challenging the UK’s waste management sector,’ notes Chris, ‘but fortunately a cost effective and versatile XRF solution is at hand.’