Positive Material Identification (PMI) of Stainless-Steel Using Handheld XRF

Introduction

Knowing exactly what’s in your stainless-steel components can save time, reduce costs, and prevent potentially serious failures. Positive Material Identification (PMI) is a non-destructive testing (NDT) method that determines the chemical composition of metals and alloys. It’s an essential step to ensure materials meet the design specifications; whether they are being installed for the first time or inspected during service.

In any refinery, or other process plant industries requiring high temperature and high pressure, safety is routinely ensured by verifying that a given alloy conforms to the design specification. A significant number of incidents in refineries and chemical plants are caused by having the wrong metal in service. By maintaining a strong PMI program – based on API 578 or internal procedures – it is possible to virtually eliminate these failures.

On the manufacturing floor or in a machine shop, alloy identification may be lost as the metal moves through the shop. Using a portable XRF alloy analyser allows immediate recovery of lost material traceability and ensures that a part is made in the proper material. And that work is done prior to investing a large amount of machining time and prior to shipment to customers.

Equipment and Sample Used – The setup

In this application, we analysed a stainless-steel pipe using the Bruker S1 TITAN 800 handheld XRF. The S1 TITAN 800, when ordered with an Alloy calibration, is automatically equipped with Bruker’s SMART Grade™ calibration. This application automatically determines the proper conditions and measurement times for each alloy measured.

The small spot camera and collimator ensure precise targeting of the measurement area, including welds or other critical features, without removing or altering the component. All the operator needs to do is simply position and pull the trigger – the S1 TITAN does the rest. This in-situ testing ensures the PMI results reflect the actual material used, not an approximation.

Measurement and Results

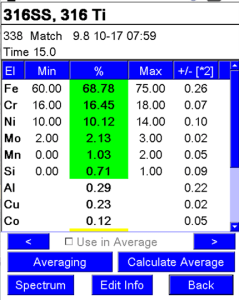

The S1 TITAN 800 provides a full elemental assay and reporting in just 15 seconds. The measured composition was 68.78% iron (Fe), 16.45% chromium (Cr), 10.12% nickel (Ni), 2.13% molybdenum (Mo), and 0.71% silicon (Si). These results were automatically compared against the instrument’s comprehensive grade library, which contains hundreds of international alloy standards.

Based on this comparison, the analyser identified the pipe as 316 Stainless Steel (316SS) with 98% certainty. The integrated camera and small spot collimator ensured that the measurement was taken precisely from the target area, including welds or other localised features, without compromising accuracy. The entire test, from positioning to grade identification, was completed instantly with reliable, and traceable PMI suitable for industrial quality control (QC/ QA) and compliance purposes.

If you are wondering how PMI checks work in hard-to-reach areas; the Bruker S1 TITAN can be paired with an Extension Pole (add on accessory). This allows operators to perform inspections safely, comfortably, and efficiently without the need for a ladder. This also extends the versatility of handheld XRF for PMI testing in complex piping, vessels, or in fabricated assemblies.

Grade Library

The S1 TITAN alloy calibration includes extensive grade libraries (1,000+ grade definitions) covering various international standards. User selectable libraries include: AISI, EN-DIN, JIS and others.

These libraries cover the following alloy classes:

- Low alloy steels

- Cr-Mo steels

- Tool steels

- Stainless steel

- Zirconium alloys

- Zinc alloys • Aluminium

- Titanium

- Exotic alloys

- Specialty alloys

- Nickel alloys

- Brasses

- Bronzes

- Cobalt alloys